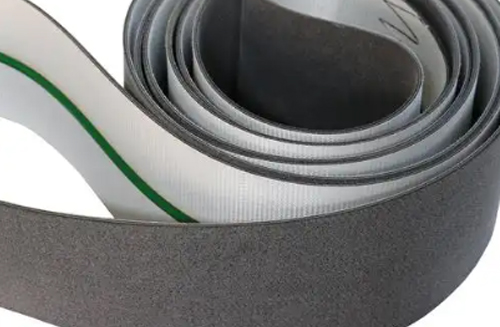

Annilte Double-sided Felt Belt for Ceramic/Glass /Cutting Machine Conveyor Belt

4.0mm Felt Conveyor Belt Features

Temperature resistance: the working temperature is generally -10℃~80℃, and the short-term high temperature resistance can reach 100℃.

Abrasion and cutting resistance: the surface felt layer has high abrasion resistance, suitable for the transportation of metal chips or sharp materials.

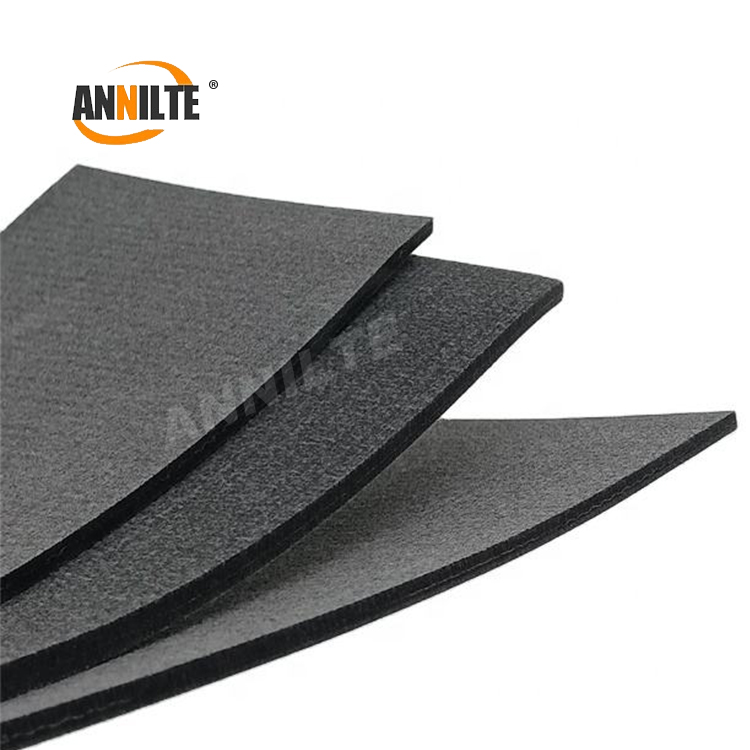

Tensile resistance: the tensile strength of the 4.0mm thickness product is ≥170N/mm, and the elongation is ≤1%.

Felt belt data sheet

|

Key words

|

Felt conveyor belt

|

|

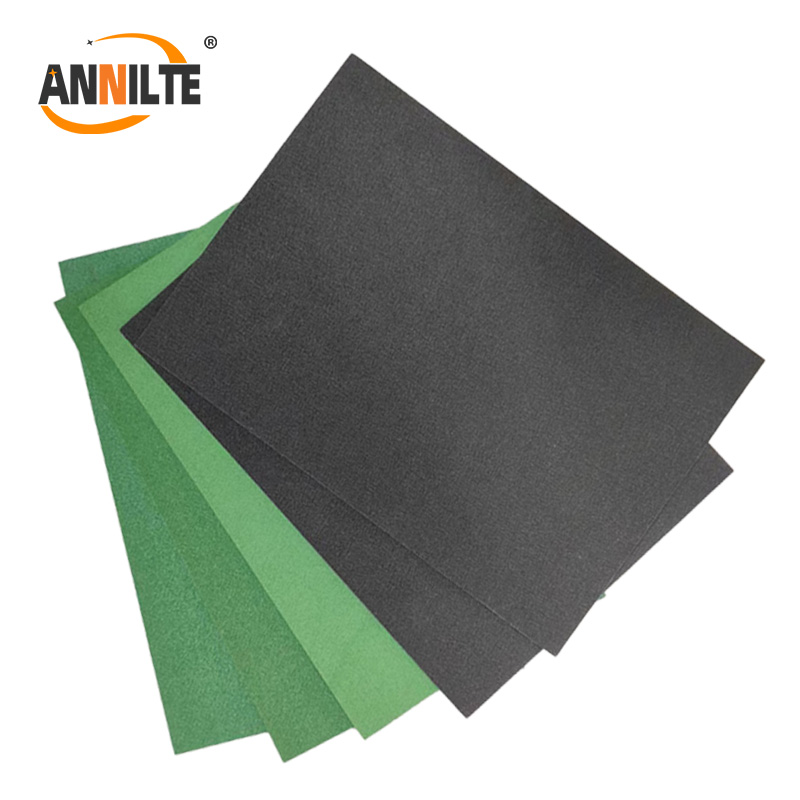

Color

|

Black and green

|

|

Thickness

|

4mm

|

|

Joint

|

Welded

|

|

Antistatic

|

109~1012

|

|

Temperature range

|

-10℃-80℃

|

|

Size

|

Customized

|

|

Max width

|

3400mm

|

Product Advantages

No pilling or linting

Made of imported German raw materials

No pilling and linting

Prevents the felt from sticking to the fabric.

Good air permeability

Uniform surface felt material

Good air permeability and air absorption

Ensures that the material does not slide or deflect

Abrasion and cut resistance

Made of high-density felt material, which can be adapted to the high requirements of high-speed cutting.

Support customization

Specification according to the different needs of customers

Can be customized

Meet customer requirements

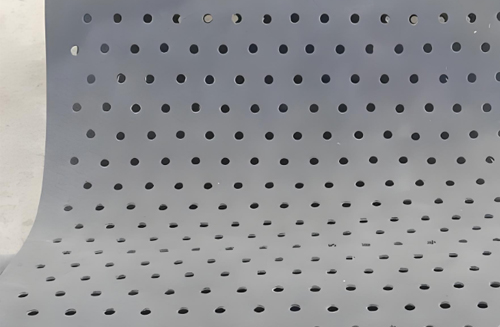

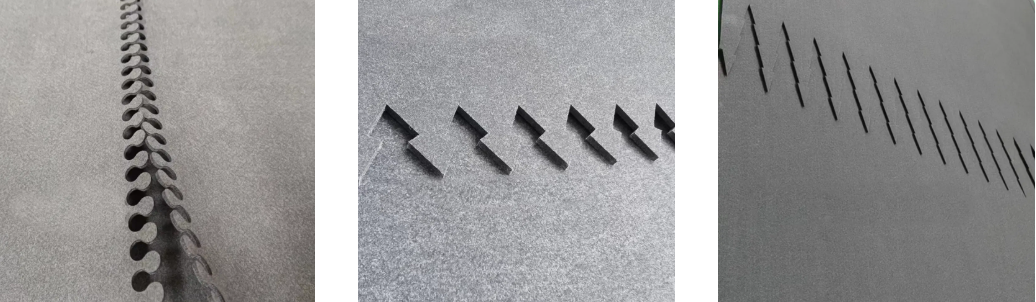

Product Process

The processing of felts includes the steps of adding guides and punching holes. The purpose of adding guides is to enhance the durability and stability of the felt and to ensure that it will not be deformed or deflected in the course of use. The holes are punched for precise positioning, air absorption and ventilation.

Felt Belt Perforation

Add Guide Bar

Common Felt Belt Joints

Toothed Joints

Skew Lap Joint

Steel Clip Connectors

Applicable Scenarios

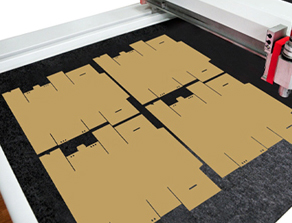

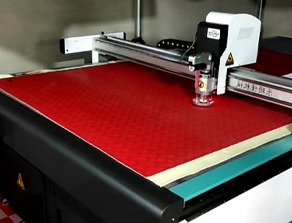

Felt conveyor belts are widely used in many fields due to their unique properties:

Light industry: such as clothing, footwear and other production lines, for conveying fragile or need to protect the goods.

Electronic industry: excellent anti-static performance, suitable for conveying electronic components or sensitive materials.

Packaging industry: for the transportation of finished packaging products to avoid abrasion or scratching of packaging materials.

Logistics and warehousing: in sorting systems for the transportation of lighter and irregular items, which effectively protects the surface of the material.

Home Furnishing

Paper Cutting Industry

Packaging Industry

Curtain processing

Bags and Leather

Automobile interior

Advertising Materials

Clothing Fabrics

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/