Annilte Flow Spinning Dragon Belt,Drive Belt Conveyor Flat Belt,Drive spindle belt

Polyester sheet base belt is an excellent transmission belt material with high strength and abrasion resistance, which can improve the transmission efficiency and stability of the equipment, reduce the operating cost, and make an important contribution to the sustainable development of the machinery manufacturing industry.

Polyester sheet base belt is usually made of polyester sheet and strong fiber weaving, with high load carrying capacity and tensile strength, able to withstand high-frequency vibration and impact. In addition, polyester sheet base tapes also have good resistance to high temperature, oil, wear and other properties, and can work in harsh environmental conditions.

In the machinery manufacturing industry, polyester sheet base belts are widely used in various transmission systems, such as vibrating knife cutting machine, conveyor, elevator and so on. Its excellent performance can improve the transmission efficiency and stability of the equipment, reduce maintenance costs and improve production efficiency.

In conclusion, as an excellent transmission belt material, polyester sheet base belt has a wide range of application prospects and market prospects. When selecting and using, it is necessary to pay attention to its applicability and quality and other factors to ensure that it can meet the requirements of use and has a better cost performance.

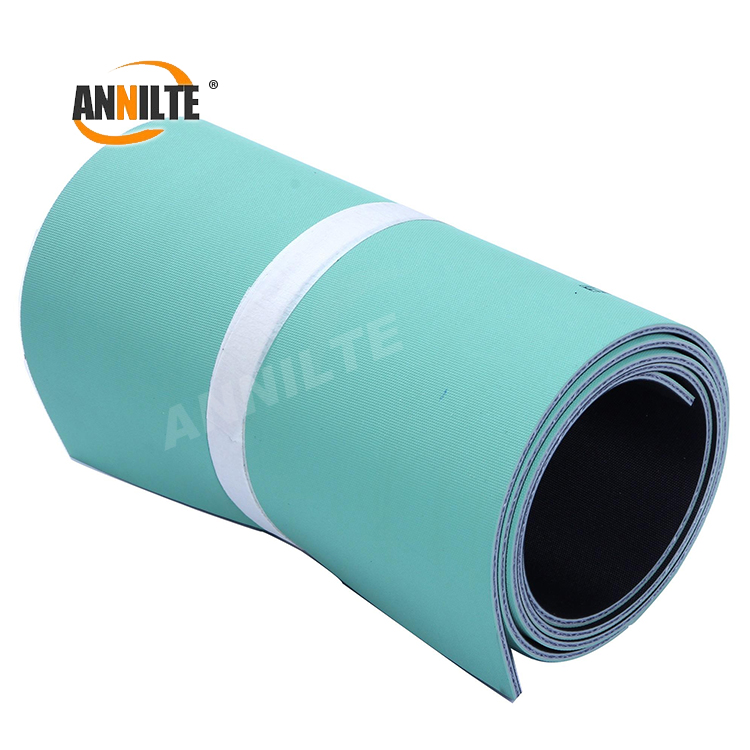

| Product Construction |

| 1 | External side material | Carboxyl Butadiene Acrylonitrile (XNBR) |

| 1 | External side surface pattern | Fine structure |

| 1 | External side color | Light green |

| 2,4 | Material | TPU |

| 3 | Traction layer (material) | PET fabric |

| 5 | Pulley side material | Carboxyl Butadiene Acrylonitrile (XNBR) |

| 5 | Pulley side surface pattern | Fine structure |

| 5 | Pulley side color | Black |

| Product Characteristics |

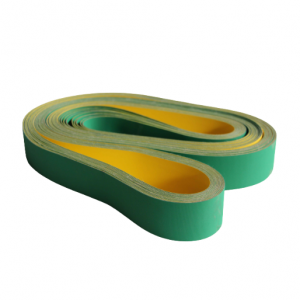

| Drive Determination | Double-sided power transmission |

| Joining method | Finger Joint |

| Antistatically equipped | Yes |

| Adhesive free joining method | Yes |

| Customization | Color, micro logo, packaging |

| Application | High speed chemical fiber double twister |

| Technical Data |

| Thickness of belt (mm) | 2.5 |

| Mass of belt (belt weight) (kg/m²) | 3.11 |

| Tensile force for 1% elongation per unit of width (N/mm) | 32.20 |

| Coefficient of friction (running side / stainless steel slider bed) | 0.8 |

| Minimum operating temperature (°C) | -20 |

| Maximum operating temperature (°C) | 70 |

| Minimum Pulley diameter (mm) | 50 |

| Seamless manufacturing width (mm) | 500 |

All data are approximate values under standard climatic conditions: 23°C, 50% relative humidity.