Annilte High temperature resistant food grade food mesh ptfe conveyor belts

Teflon conveyor belt is also known as Teflon conveyor belt, PTFE conveyor belt and high temperature resistant conveyor belt.

Specific attributes

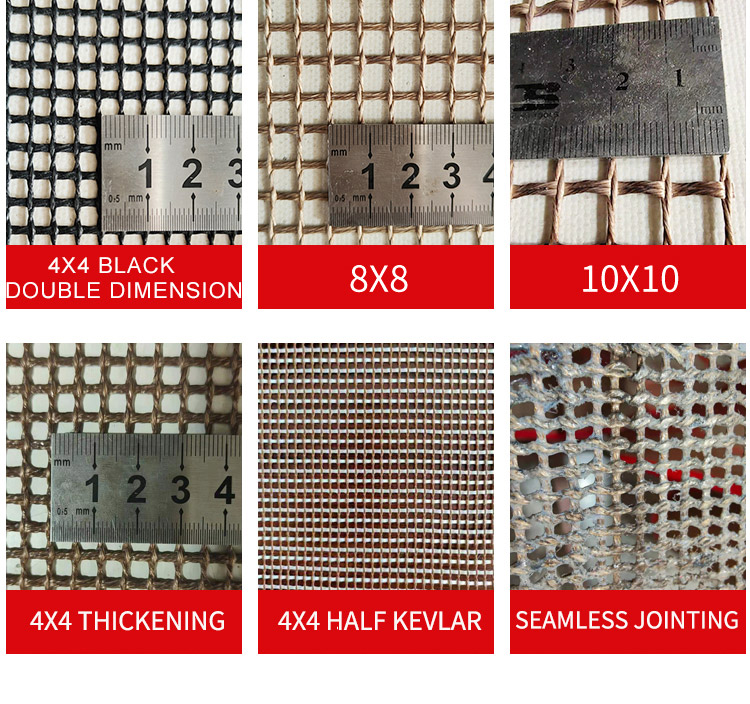

| Model | Color | Mesh size | Max. width | Weight | PTFE content | Tensile strength |

| AN6003 | Black | 4*4mm | 3600mm | 480g/sqm | 32% | 1330/1700 N/5CM |

| AN6004 | Brown | 4*4mm | 3600mm | 475g/sqm | 31% | 3200/1700 N/5CM |

| AN6008 | Brown | 4*4mm | 3600mm | 560g/sqm | 27% | 1700/2600 N/5CM |

| AN6008S | Brown | 4*4mm | 3600mm | 680g/sqm | 32% | 2520/3500 N/5CM |

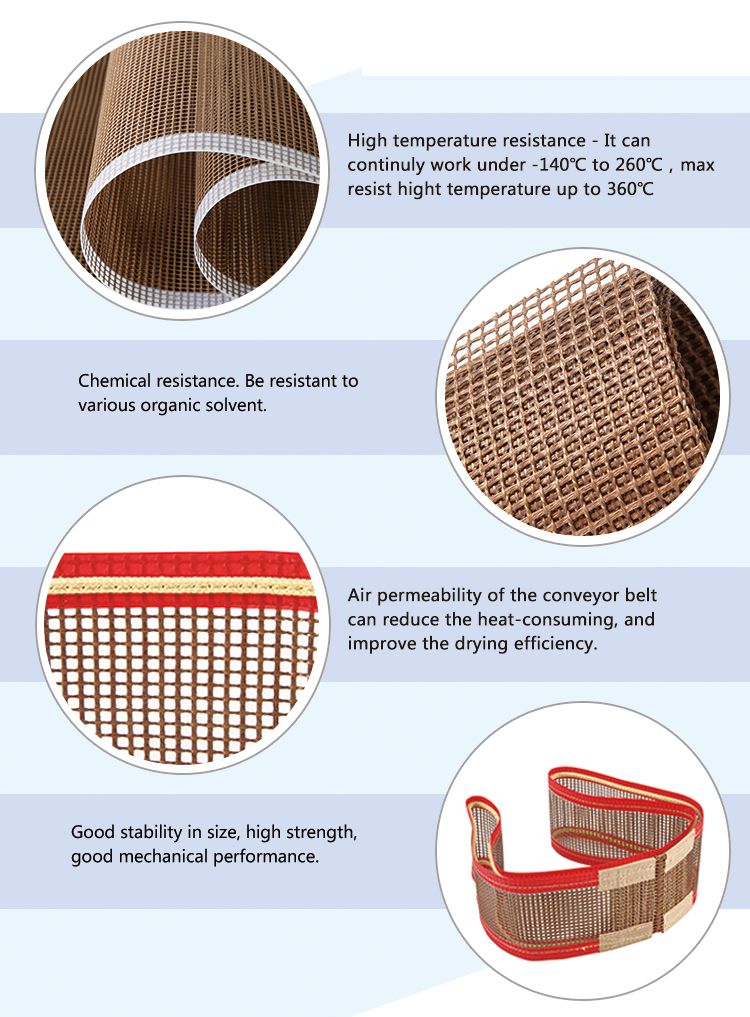

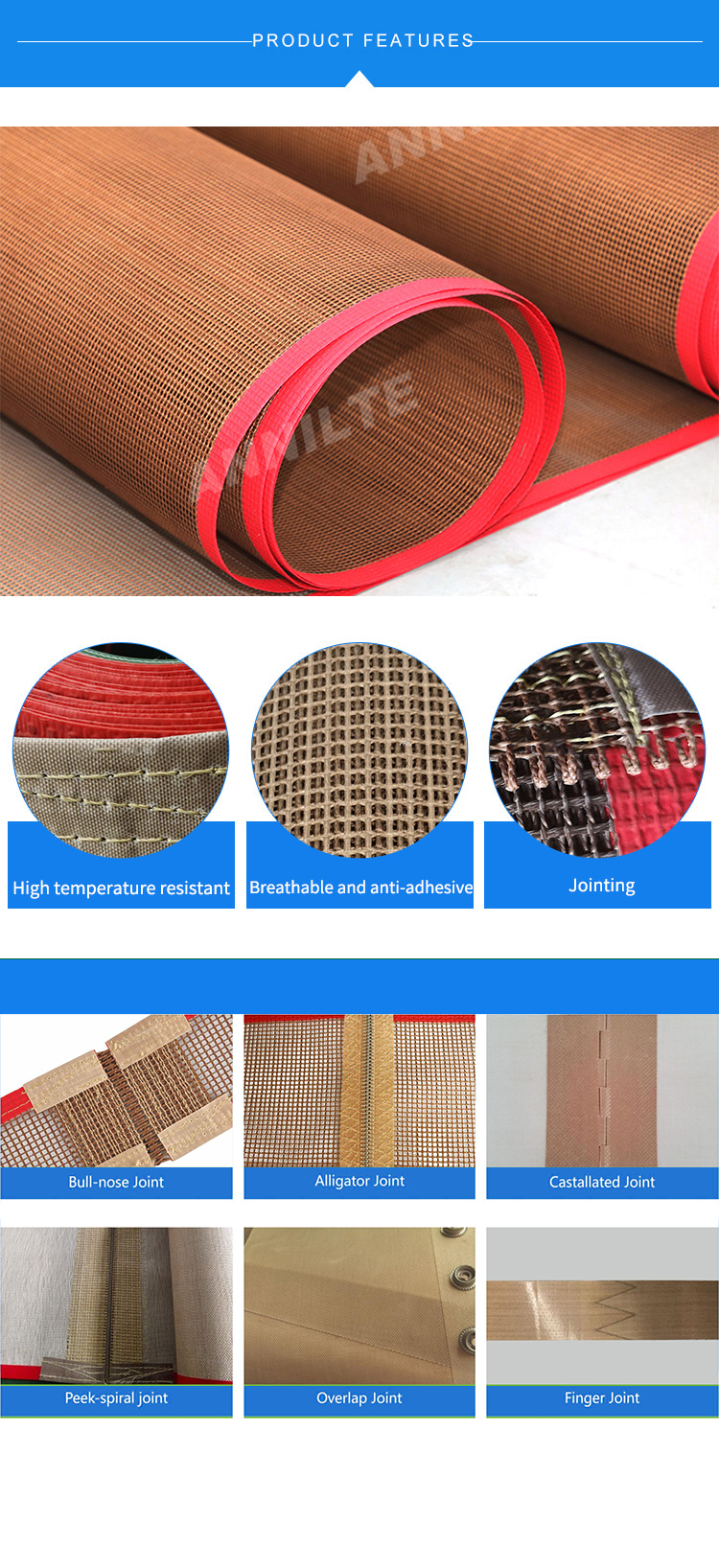

Main features

Temperature resistance: Teflon mesh belt can work stably between low temperature -70℃ and high temperature 260℃, with excellent weather resistance and anti-aging properties. It has been verified by practical application that there is no significant change in its strength and weight when it is placed continuously at a high temperature of 250℃ for 200 days.

Non-adhesion: the surface of the mesh belt is not easy to adhere to any substance, easy to clean all kinds of oil stains, stains or other attachments attached to its surface. Almost all adhesive substances such as paste, resin, paint, etc. can be simply removed.

Chemical resistance: Teflon mesh belt is resistant to strong acids, alkalis, aqua regia and various organic solvents, showing excellent chemical stability.

Dimensional Stability and Strength: The mesh belts have good dimensional stability (elongation coefficient less than 5‰) and high strength, which ensures their reliability and durability in a variety of applications.

Other characteristics: It also includes resistance to bending fatigue, pharmaceutical resistance, non-toxicity, fire retardant, good air permeability and other characteristics. These characteristics make Teflon mesh belt widely used in many industrial fields.

Application Scope

Teflon mesh belt is widely used in the following fields because of its excellent performance:

Textile, printing and dyeing: such as printing drying, bleaching and dyeing fabric drying, fabric shrinkage drying, nonwoven fabric drying and other drying channel, drying room conveyor belt.

Screen, printing: such as loose drying machine, offset printing machine, UV series of light solid machine, paper over oil drying, ultraviolet drying, plastic products screen printing drying and other drying channel, drying room conveyor belt.

Other items: such as high-frequency drying, microwave drying, various types of food freezing and defrosting, baking, packaging items heat shrinkage, general moisture content of the drying of goods, rapid drying of the melt-type ink, such as drying room guide belt.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/