ANNILTE Intelligent Garbage Sorting Conveyor Belt

Annilte Waste Sorting Conveyor Belt

Ordinary conveyor belts often face the problem that the baffle plate is easy to fall off in the process of using, which not only affects the sorting efficiency, but also increases the maintenance cost. In response to this phenomenon, ANNI, with its advanced production technology and rich industry experience, has successfully developed a whole bottle sorter belt that is popular among environmental protection equipment manufacturers and renewable resource sorting centers.

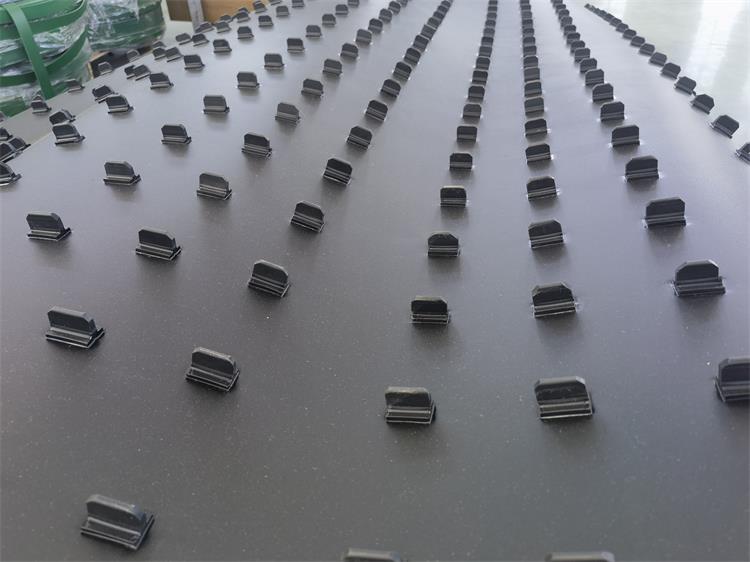

Baffle design

Annilte's baffles are customized according to the requirements of customer's equipments, which are easy to turn and well oriented. Adopting German superconducting vulcanization technology, the baffle plate and the bottom belt are fused into one, with a high degree of adhesion, effectively solving the problem of frequent cracking and falling off of the baffle plate.

Tension and machine test

Each whole bottle sorter belt has gone through strict tensile test and on-board test to ensure that the baffle can still maintain good working condition under high speed operation.

Anti-running design

Annilte adopts infrared positioning and diagonal cutting process to ensure that the belt size is accurate and does not run off. At the same time, the guide strips are designed according to the actual working conditions to maintain good guidance under high-speed operation and reduce the turning force of the guide strips.

We customize the whole bottle sorter belts according to the customer's industry, equipment and working conditions to ensure the best performance in the actual application.

Why Choose Our Sorting Belt

Efficient Cutting

Annilte garbage sorting conveyor belt solves the problems of ordinary conveyor belt not being wear-resistant, guide bar falling off easily, baffle plate cracking and falling off easily, and conveyor belt running out of shape.

Strong durability

Annilte garbage sorting conveyor belts are made of more than 200 kinds of raw materials, and no less than 300 times of chemical agent corrosion resistance and object abrasion tests have been carried out to improve the adhesion between the belt cores and enhance the abrasion resistance of the belts, so that the service life of the belts can be extended by 2-3 times compared with that of the ordinary conveyor belts.

Strong customization

The garbage sorting conveyor belt developed by Jinan Annilte has been successfully applied in the field of garbage disposal of domestic, construction and chemical products. According to more than 200 garbage disposal manufacturers in the market, the conveyor belt operates stably, and with the increase in conveying capacity during the process of use, there is no problem of cracking and durability of conveyor belts, which helps the sorting industry to achieve considerable economic benefits.

Applicable Scenarios

Garbage sorting conveyor belt is suitable for PET bottle production cleaning and recycling line, bottle flake cleaning and recycling line equipment, bottle flake processing plant, film cleaning and recycling line equipment, bottle flake crusher and other fields.

Garbage sorting conveyor belt is mainly used in renewable resources industry for recyclable garbage sorting, urban living garbage sorting, construction and decoration garbage sorting, such as PET bottles, PP lunch boxes, cans, clothes, shoes, glass bottles and other items, which can be sorted into dozens of kinds of recyclable garbage, and it is suitable for baling station, urban garbage recycling and processing station and so on.

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/