Annilte PP Poulry Manure Conveyor belts For Chicken Farm

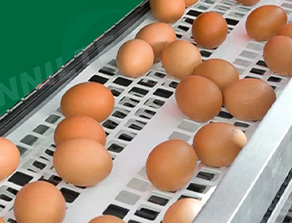

The manure cleaning belt is also called manure conveyor belt, used for chicken, duck, rabbit, quail, pigeon, etc. to catch manure transmission, the manure cleaning belt is mainly applied to the manure transportation of caged poultry, which is a part of the manure cleaning machine. The manure conveyor belt is usually bright milky white color, unique performance, improved tensile strength, impact resistance, low temperature resistance, strong toughness, corrosion resistance, low coefficient of friction, this kind of manure conveyor belt can be adapted to a variety of working environments.

The Specifications of Manure Belt

| Part number | Name | Material | Thickness (mm) |

Weight (kg/㎡) |

Temperature range (℃) |

| AN-P001 | manure belt | Polypropylene | 0.8 | 0.76 | -40~90 |

| AN-P002 | manure belt | Polypropylene | 1 | 0.94 | -40~90 |

| AN-P003 | manure belt | Polypropylene | 1.2 | 1.14 | -40~90 |

| AN-P004 | manure belt | Polypropylene | 1.5 | 1.41 | -40~90 |

| AN-P005 | manure belt | Polypropylene | 2 | 2.7 | -40~90 |

Advantages of manure belts

Acid and alkali resistance

It has good acid and alkali resistance and anti-corrosion performance, and will not be eroded by feces, which effectively prolongs the service life of the manure belt and reduces the replacement frequency.

low temperature resistance

Adding antioxidant and cold-resistant agent in the raw material, the low temperature resistance performance is improved by 50%, and it can operate normally in the low temperature environment of minus 40℃.

Good raw materials

made of virgin PP material, with antibacterial, acid and alkali resistance, corrosion resistance, easy to clean and so on.

Support customization

Length ,width and Thickness can be customized, Customized perforation,commonly used thickness, 1.0mm, 1.2mm, 1.5mm, 2.0mm.

Type of Manure Cleaning Belt

More and more manufacturers start to use manure removal belt to treat chicken manure, which makes the work of manure cleaning become simple and efficient, and the cost of manpower is also greatly reduced. Anai's technicians are deeply engaged in the field of manure cleaning belt, and have conducted market research and visited more than 3000 chicken farms. The main types of manure cleaning belts used are PP manure cleaning belt and knife and scraper cloth manure cleaning belt.

Applicable Scenarios

The manure cleaning belt is mainly used for manure cleaning of caged poultry such as chickens, ducks, rabbits, quails, pigeons and so on. At a time when industrial automation is becoming more and more popular, large-scale farms commonly use manure cleaning belts to improve the efficiency and accuracy of manure cleaning.

Quail Farming

Duck Farm

Rabbit Farm

Spotted Dove Farming

Pigeon Farming

Snake Farm

Food Industry

Chicken Manure Drying

Laboratory

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

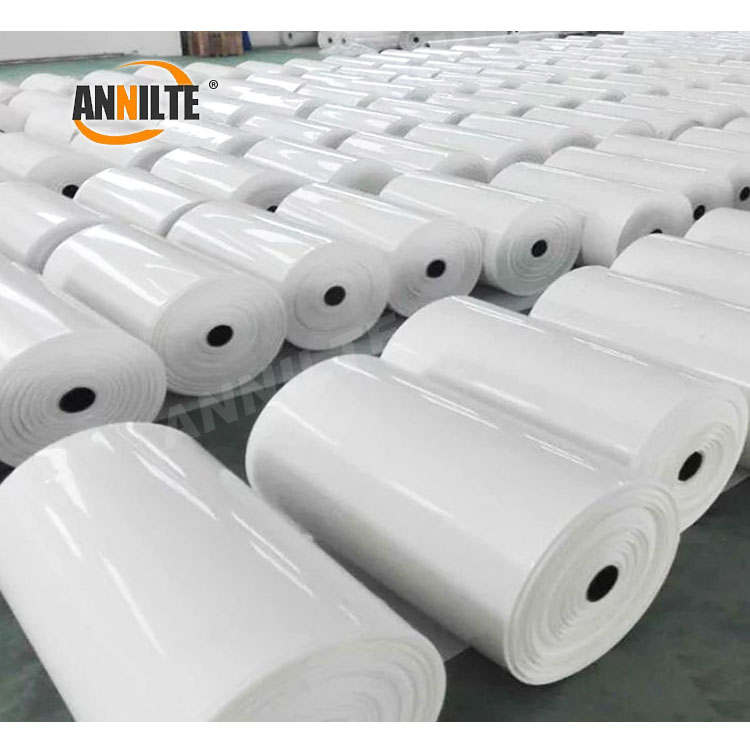

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/