Annilte Mineral Processing Blanket Belt for ferromolybdenum ore /Tungsten-Tin Ore /Lead-Zinc Ore

Mineral beneficiation felt conveyor belts are mainly used for ore transportation in the beneficiation process, including the following areas:

Iron ore beneficiation. Mineral processing felt conveyor belts can be used in iron ore conveying, grinding and flotation processes.

Copper Ore Beneficiation. Beneficiation felt conveyor belts can also be used in processes such as conveying, grinding and flotation of copper ores.

Tin Ore Beneficiation. Mineral processing felt conveyor belts can be used in processes such as tin ore conveying, sorting and flotation

As the market of mineral processing felt belt mixed, if greedy for cheap choose to poor quality felt belt, in use is very easy to appear felt breakage, fall problem, not only affect the service life of the felt belt, but also seriously affect the efficiency of mineral processing, to the enterprise caused huge economic losses.

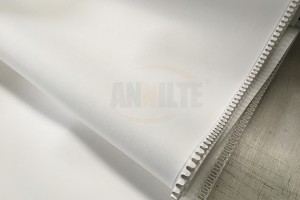

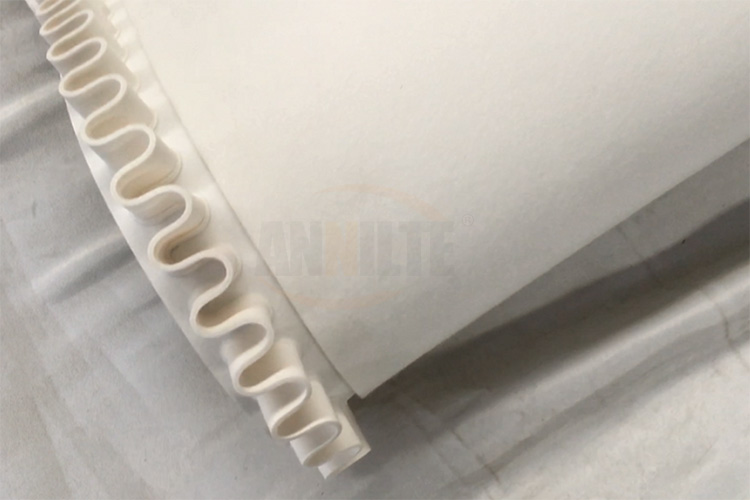

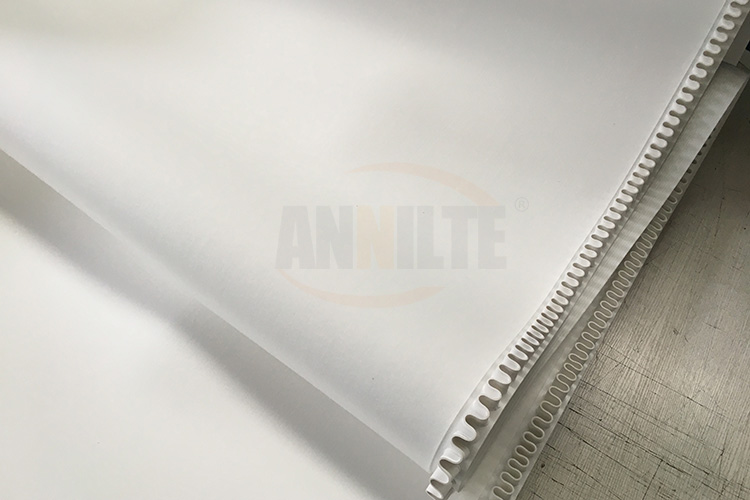

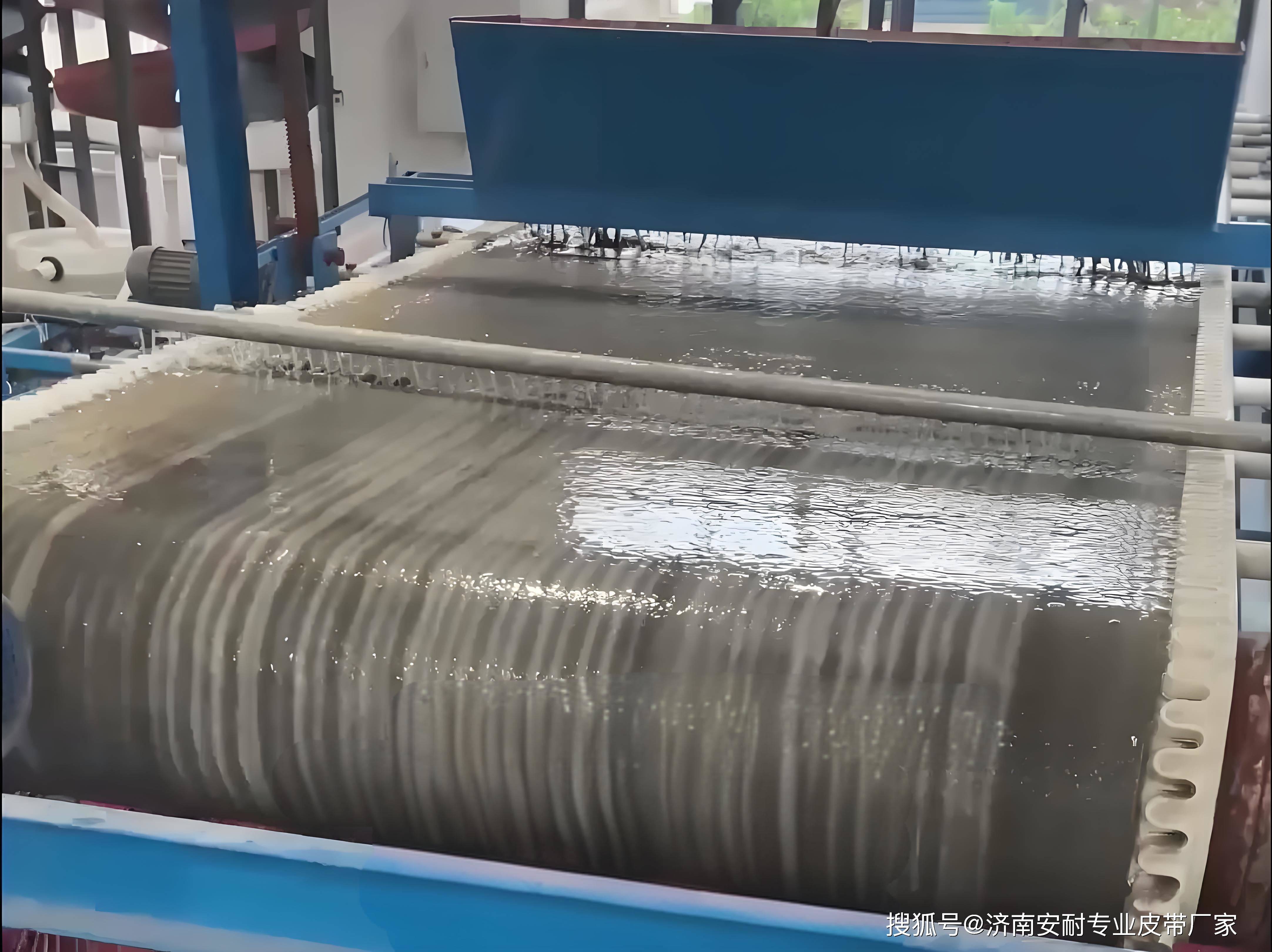

After many times of technical research and development and process improvement, it realizes the 0-distance fit between the skirt and the blanket, completely abandoning the process of large gaps between the skirt and the blanket on the market, and eliminating the waste of ore slurry loss from the gaps, and truly not running out of material!

We have targeted solutions for different equipment models and ore types through deep cooperation and joint research and development with mineral processing equipment manufacturers!

Our Product Advantages

1、 Good raw materials

Imported needle-punched wool is selected, which is highly absorbent and hydrophobic, and the blanket does not deform while hanging on the mineral powder;

2、 Good craftsmanship

Seamless skirt plus specific slow S arc, to ensure that the conveyor belt in use does not hide the material, no leakage, no material run;

3、 High beneficiation rate

Advanced needle punching process increases the effect of ore retention and enhances the beneficiation rate by 70&, two are better than three;

4、 Long service life

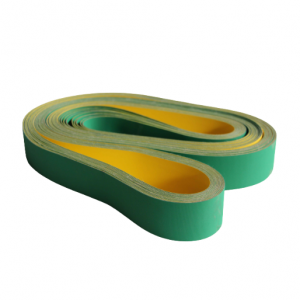

The bottom belt adopts A+ grade raw rubber, good flexibility, anti-aging, hydrolysis resistance, good flexibility, long service life.

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/