Annilte Polyurethane PU Food Grade Conveyor Belt

PU conveyor belt, i.e. polyurethane conveyor belt, is a kind of conveyor equipment made of polyurethane as the main material, which is widely used in many industries, such as food, medicine, electronics, logistics, printing and so on. Its core features are environmentally friendly materials, superior performance, and the ability to meet high standards of industrial production needs.

Specification of PU Conveyor Belt

| Color: | Thickness (mm) | Face | Ply | Feature | Temperature |

| White PU conveyor belt | 0.8~3.0 | Glossy / Matte | 2ply,4ply | Food Grade ,Oil Resistant | -10°C — +80°C |

| Blue PU conveyor belt | 1.5~2.0 | Glossy / Matte | 4ply | Food Grade, Oil Resistant Anti-mold and Anti-bacteria | -10°C — +80°C |

| Black PU conveyor belt | 1.0~4.0 | Matte | 2ply,4ply | Wear-resistant, oil-resistant, anti-static | -10°C — +80°C |

| Dark green PU conveyor belt | 0.8~4.0 | Matte | 2ply,4ply,6ply | Wear-resistant, oil-resistant, anti-static | -10°C — +80°C |

| Cut-resistant PU conveyor belt | 4.0~5.0 | Matte | 4ply | Wear-resistant, oil-resistant, cut-resistant | -10°C — +80°C |

Advantages of Annilte PU Conveyor Belt

Material and Structure

Substrate: High-strength synthetic polyurethane fabric is used as the load-bearing skeleton to ensure the tensile strength and stability of the conveyor belt.

Coating layer: The surface is coated with polyurethane resin to form a smooth, wear-resistant and oil-resistant conveying surface.

Characteristics: Polyurethane material is non-toxic, odorless and environmentally friendly, which meets the food-grade hygiene standard and can be directly contacted with food.

Advantages of Food Belts

Customized Scope

Annilte offers a wide range of customization options, including band width, band thickness, surface pattern, color, different processes (add skirt, add baffle, add guide strip, add red rubber), etc., which can meet the needs of different customers.

For example, the food industry may need oil and stain resistant properties, while the electronics industry needs anti-static properties. No matter which industry you are in, Annilte can customize for you to meet the needs of various special working conditions.

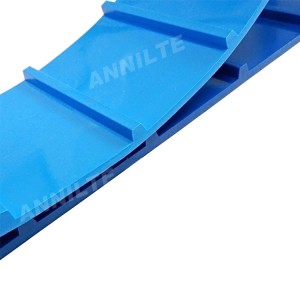

Add skirt baffles

Guide bar processing

White Conveyor Belt

Edge Banding

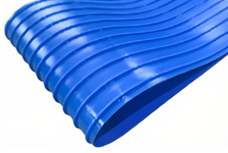

Blue Conveyor Belt

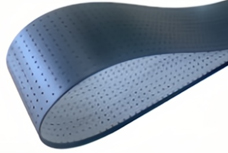

Sponging

Seamless Ring

Wave processing

Turning machine belt

Profiled baffles

Applicable Scenarios

Food industry: used for conveying, processing and packaging of cookies, candies, fruits and vegetables, meat, aquatic products and other food products, suitable for baking, slaughtering, frozen food and other production lines.

Pharmaceutical industry: material conveying in the process of drug production and packaging, to ensure drug hygiene and safety.

Electronic industry: dust-free conveying of electronic components and precision instruments to prevent static electricity and pollution.

Dough Conveyor Belt

Aquatic Products Processing

Meat Processing

Bread Production Line

Vegetable Cutting, Medicine Cutting

Vegetable Sorting Line

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/