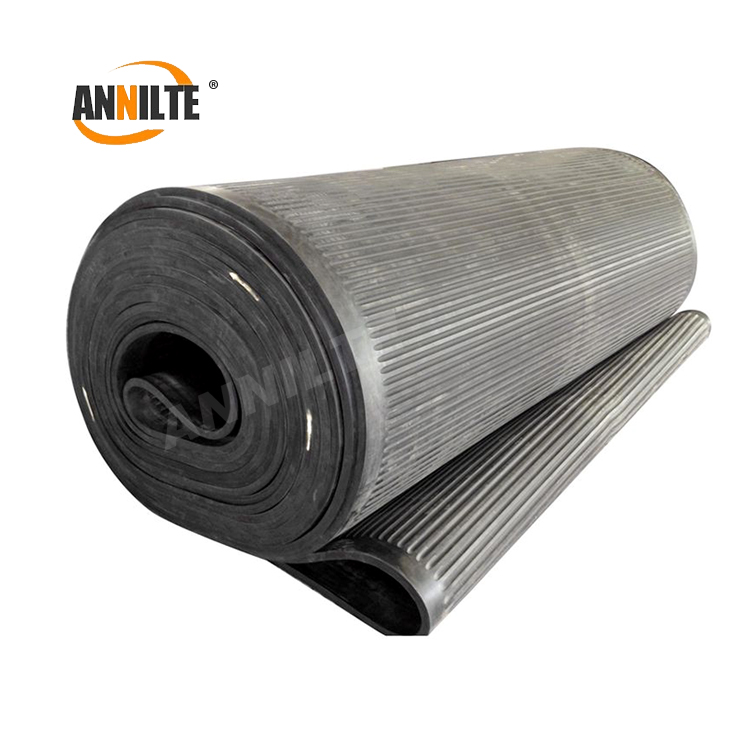

Annilte Horizontal Customize Vacuum Belt Filter Belt for Minerals Metallurgy

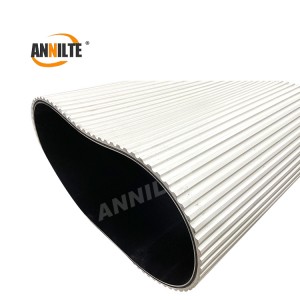

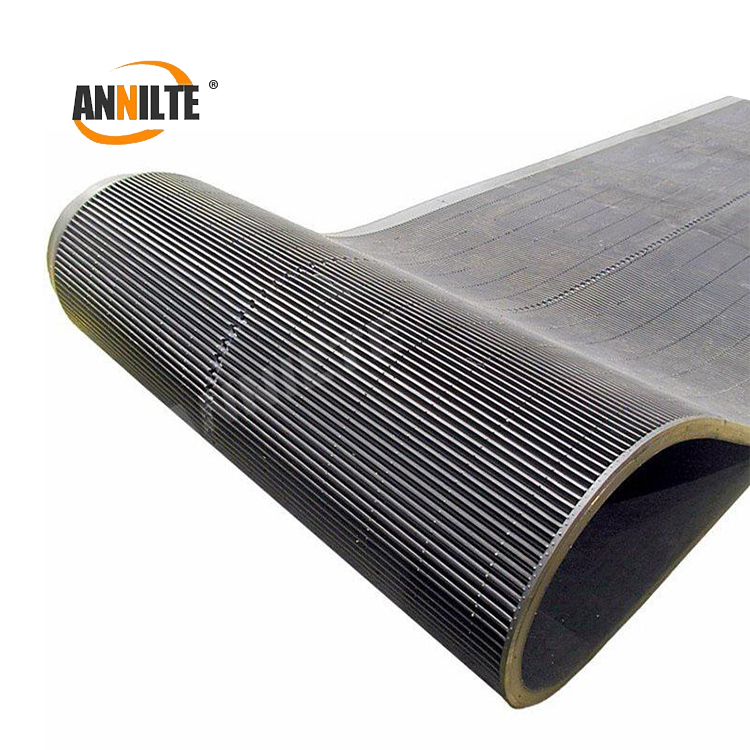

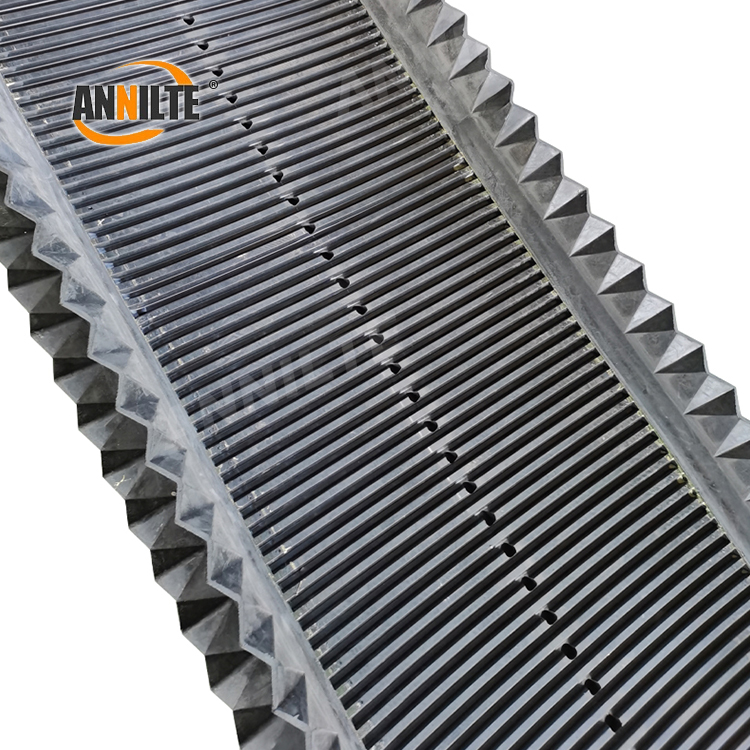

A vacuum belt filter belt, also known as a vacuum belt or horizontal belt vacuum filter tape, is the core component of a belt vacuum filter. It is usually a circular continuous rubber belt with a filtering surface connected to the vacuum tank, and the belt is designed with regularly arranged transverse grooves, which are equipped with single or multiple rows of liquid holes for discharging the filtrate during the filtration process.

The Specifications of Annilte Vacuum Filter Belt

Max-Width: 5.8 meters

Width: 1 meter, 1.2 meters, 1.4 meters, 1.6 meters, 1.8 meters mainly

Thickness: 18mm---50mm, 22mm---30mm .

Height of skirt: 80mm,100mm,120mm,150mm

Our Product Advantages

High abrasion resistance:

adapt to the abrasion of mining and metallurgical materials.

Corrosion resistance:

resist chemical corrosion, prolong service life.

High-efficiency filtration:

quickly separating solids and liquids, enhancing production efficiency.

High strength:

withstand high tension to ensure stable operation.

Product Categories

1、Acid and alkali resistant filter belt

Features:Acid and alkali resistant, corrosion resistant, high strength, long life and so on.

Application Scenario:It is suitable for fields in contact with acid and alkali, such as phosphate fertilizer, alumina, catalyst and so on.

2、Heat-resistant filter belt

Features: High temperature resistance, aging resistance, high tensile strength, and long service life.

Application Scenario:Mainly used for filtering high temperature materials, 800°C-1050°C.

3、Oil-resistant filter belt

Features: It has the advantages of low deformation and change rate of the belt body, high strength and wide range of use.

Application Scenario: It is suitable for filtration of various oil-containing materials.

4、Cold resistant filter belt

Features: high elasticity, impact resistance, cold resistance and other characteristics.

Application Scenario: It is suitable for the working environment with the temperature ranging from -40°C to -70°C.

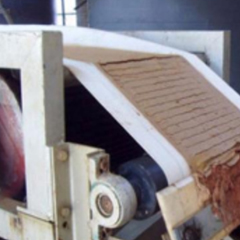

Applicable Scenarios

Applications: solid-liquid separation in metallurgy, mining, petrochemical, chemical, coal washing, paper making, fertilizer, food, pharmaceutical, environmental protection, gypsum dehydration in flue gas desulfurization, tailings treatment and other industries.

Petrochemical Filtration

Petrochemical Filtration

Iron Ore Filtration

Calcium Sulfate Filtration

Desulfurization Filtration

Copper Sulfate Filtration

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.