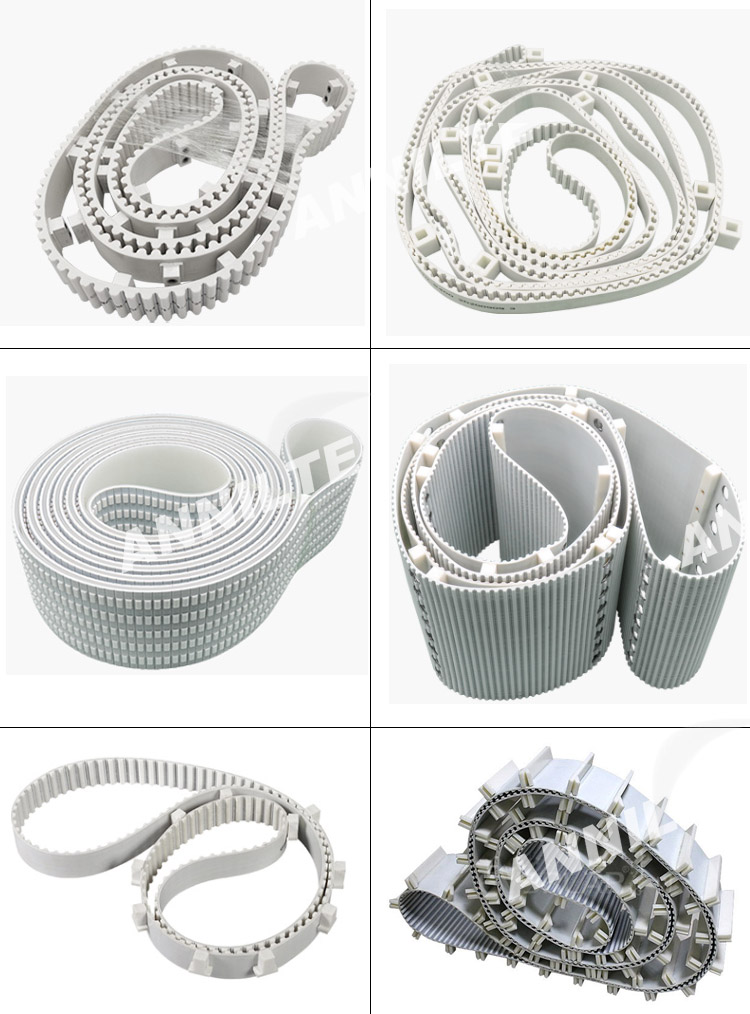

Annilte STD HTD 5M 8M 14M 20M XL L T5 T10 AT5 AT10 AT20 H XH polyurethane timing belt with any cleats

Polyurethane (PU) timing belts are made of a new thermoplastic polyurethane material with high resistance to wear and tear. With various types of steel wire core to ensure its good running ability even in high load transmission. Tenging polyurethane timing belts can be produced as open-end belts, splice ring belts and interfaceless ring belts.

Annilte polyurethane synchronous belts have the following characteristics.

1、Good wear resistance

2、Maintenance free

3、High efficiency (can reach 98%)

4、Environmental protection, low noise, energy saving

5、Can operate normally at -5℃ to +80℃

6、Not affected by humidity, UV and ozone

7、Good oil resistance and corrosion resistance

Polyurethane synchronous belt model

Polyurethane synchronous belt trapezoidal teeth: can be divided into imperial and metric system Metric system: T5, T10, T20, AT5, AT10, AT20, and T2, T2.5, T4.5, T14 Inch system: MXL, XL, L, H, XH, XXH Circular teeth: are metric system HTD3M, HTD5M, HTD8M, HTD14M, STD5M, STD8M, RPP5M. STD8M, RPP5M, RPP8M, RPP14M Unusual: HTD1.5M, HTD2M, HTD4.5M, STD2M, STD4.5M (Large quantity can be customized by mold)

Three main uses of timing belt with baffle

1. According to the size and shape of the conveyed products, the back of the synchronous belt is processed with the right size baffle, which can protect the products from falling off when conveying them.

2. Can be accurately positioned, such as the conveyor belt of the coding machine, in a certain distance there are requirements for induction, you can process the baffle plate according to the required distance, so that it can play the role of accurate induction.

3. According to the size of different materials to choose different specifications of the baffle, can be fixed, storage materials, to play the role of alternate transport products apart.