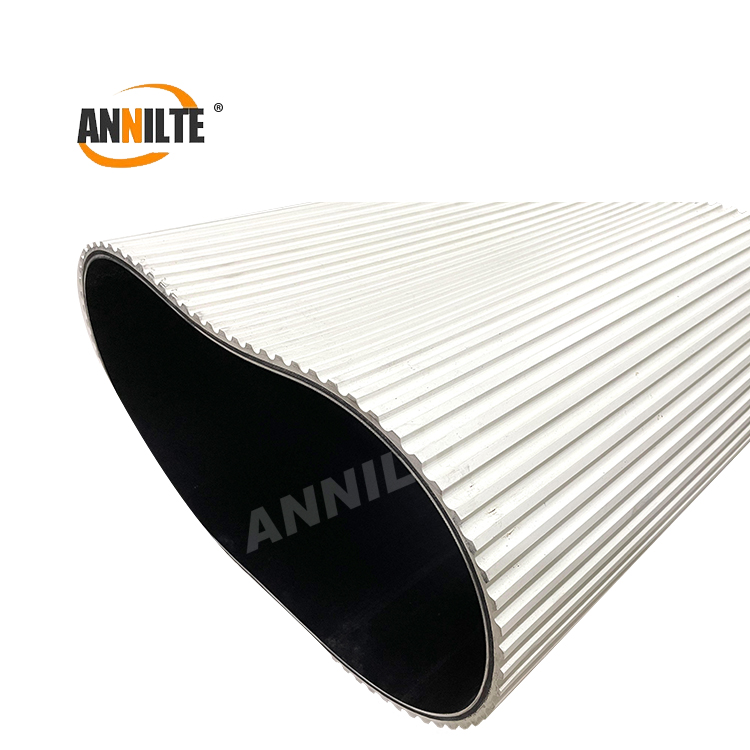

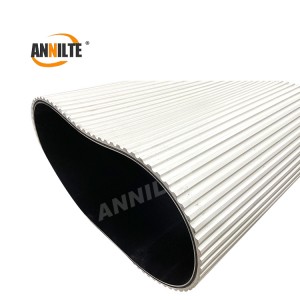

Annilte white Peanut peeling machine belt for peanut sheller machine and Peanut groundnut peeling machine

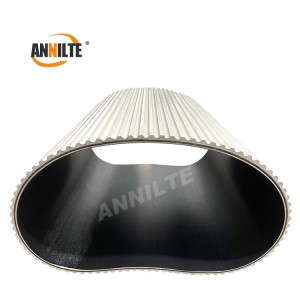

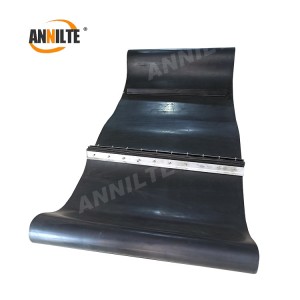

Peanut peeling machine belt is also called peanut half grain machine belt, peanut shelling / peeling machine belt, peanut rice off red coat, working principle: a long and a short with the use of . The long belt is ring-shaped at the bottom, and the short belt is open and fixed on the top of the machine. When the dried peanuts fall onto the ring belt, the peanuts will follow the teeth of the belt into the lower part of the upper belt, through the misalignment of the teeth of the upper and lower belts, the peanuts will be squeezed into halves and the peanuts will be stripped of their red skins.

Our Product Advantages

1. Precise peeling, half rate up to 98%

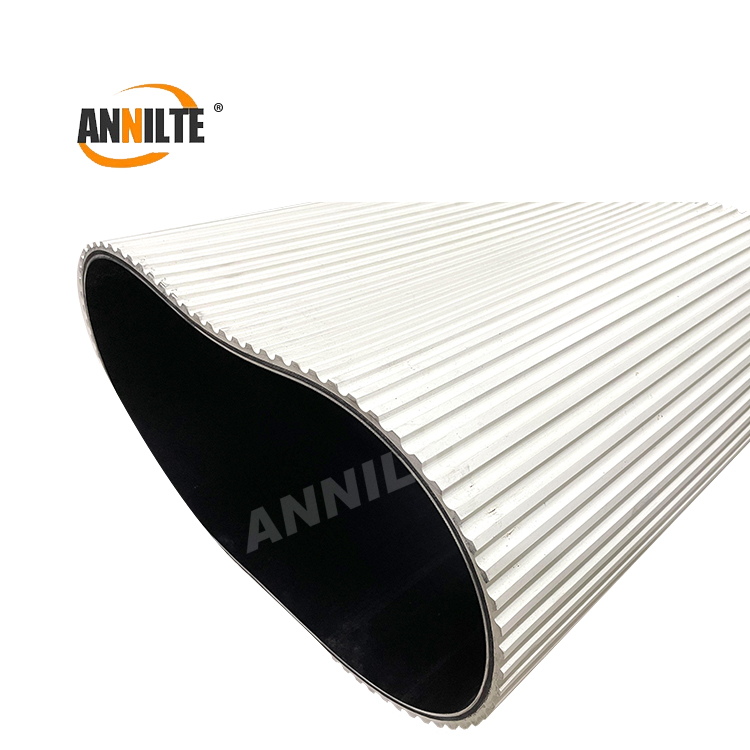

Customized specifications: peripheral length of 1500 × 601 × 13.5mm, tooth spacing Φ6 (small peanuts) / Φ9 (large peanuts), flexible to adapt to different raw materials.

Working principle: original “upper and lower double belt staggered extrusion” technology, long belt ring-shaped bottom, short belt opening fixed above, through the teeth of the precise bite, a complete peeling, halving, de-sprouting, screening and grading, the degree of automation industry-leading.

2. Food-grade safety, zero pollution

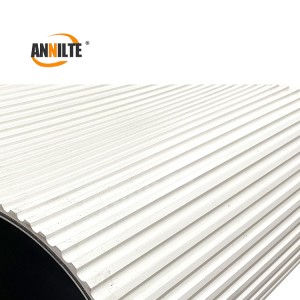

Material innovation: food-grade natural rubber + high purity silica, through the FDA food contact certification, to eliminate the risk of plasticizers.

Wear-resistant upgrade: the surface is covered with nano-scale wear-resistant coating, which reduces the rate of slagging by 90% and ensures that the finished peanuts are clean and free of impurities.

3. Flexible extrusion, crushing rate <5%

Formulation optimization: add elastomer buffer layer, rubber hardness precisely regulated, not only to ensure the peeling efficiency, but also to avoid hard rubber extrusion resulting in peanut crushing.

Process upgrading: full numerical control refining process, light inspection of internal air bubbles after vulcanization, yield rate > 99%, to eliminate belt cracking and blistering problems.

Applicable Scenarios

Peanut peeling machine belts are used throughout the whole chain of peanut processing, from primary processing in the field to deep processing in food factories, from equipment matching to after-sales maintenance, which is a key component to ensure the efficiency, quality and safety of peanut processing. The diversity of its application scenarios also promotes the development of belt technology in the direction of food-grade, wear-resistant and customized.

Peanut butter/peanut crumble production: In the food processing process of peanut butter and peanut crumble, peanuts need to be de-skinned first to remove the shells and red coats to ensure that the finished products have a fine texture and are free of impurities.

Peanut oil pressing: Peanut kernels after peeling contain fewer impurities, which can improve the oil yield and oil quality, and prolong the storage cycle of oil.

Bakery products (peanut filling): Used for making moon cakes, pastries and other peanut filling raw materials, the peanuts are easier to grind after peeling, and the filling has a more uniform texture.

Leisure food (alcoholic peanuts): Peanuts need to be peeled, split in half, fried and other processes, peeling is the first step in processing, directly affecting the finished product appearance and taste.

In the field of peanut deep processing, whether it is mellow peanut butter, crunchy peanut crumbles, or the traditional gourmet alcoholic peanuts, the source of its production can not be separated from a “clean” peanut. We specialize in peanut machinery and equipment manufacturers and terminal food production enterprises, to create food-grade peanut peeler belt, to solve the industry pain points with technological innovation, help peanut processing industry to efficient, standardized, safe upgrade!

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/