High-quality PU food conveyor belt factory

Conveyor belts have long been the backbone of industrial manufacturing, facilitating the seamless movement of goods throughout production lines. The food industry, in particular, places immense emphasis on maintaining strict hygiene standards and minimizing contamination risks. This is where PU conveyor belts come into play, offering a versatile and efficient solution that addresses the unique challenges faced by the sector.

|

Name

|

PU conveyor belt

|

|

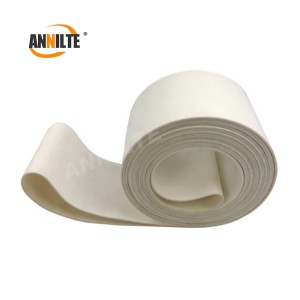

Total thickness

|

0.8 – 5mm or Customilzed

|

|

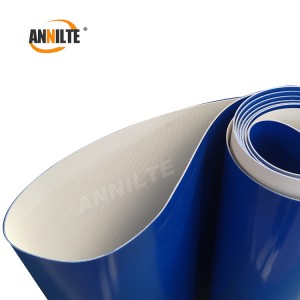

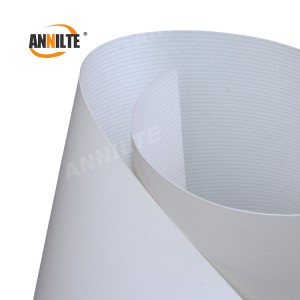

Color

|

White Green Black Gray Blue or customized

|

|

Surface

|

Flat Matte or Customized Pattern

|

|

Working temperature

|

-10—+80 (℃)

|

|

1% stress extension

|

8N/mm

|

|

Delivery time

|

3~15 days

|

Benefits of PU Conveyor Belts for the Food Industry

-

Hygiene and Cleanliness: PU conveyor belts are inherently resistant to oils, fats, and chemicals, which are commonly found in food production environments. Their non-porous surface prevents the absorption of liquids, ensuring easy cleaning and preventing the growth of bacteria. This quality is crucial in adhering to stringent food safety regulations.

-

Durability and Longevity: The food industry operates at a rapid pace, with continuous processing and high volumes. PU conveyor belts are designed to withstand the rigorous demands of such environments, offering exceptional wear resistance and a longer service life compared to traditional materials.

-

Product Integrity: PU belts are engineered with a soft yet strong material that minimizes the risk of damage to delicate food products during transportation. The gentle grip of the belt prevents items from getting crushed or misshapen, maintaining the visual appeal and quality of the food products.

-

Reduced Maintenance: The durability of PU conveyor belts translates to reduced downtime and maintenance costs. This benefit is not only financial but also contributes to uninterrupted production cycles, improving overall operational efficiency.

-

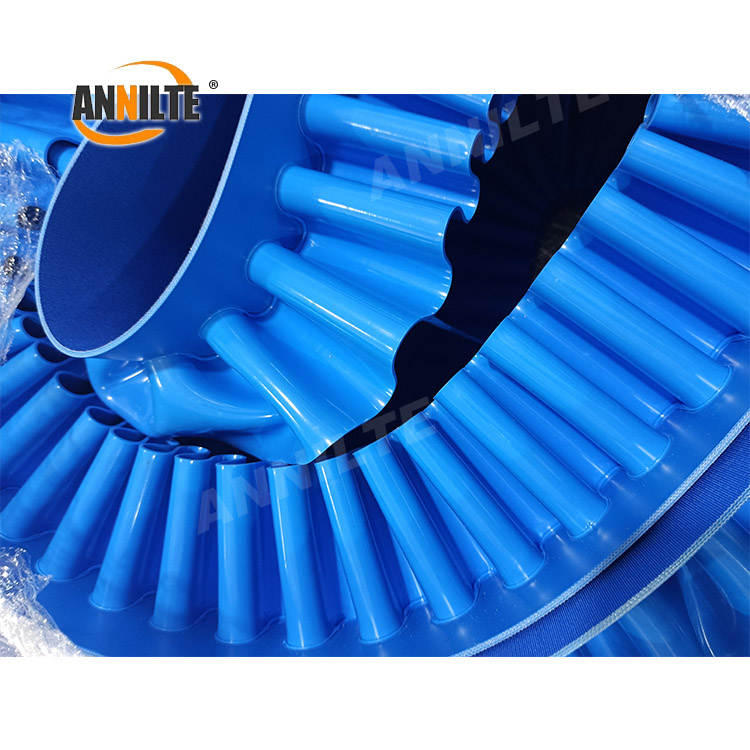

Customization: PU belts can be tailored to suit specific food industry needs. They are available in various thicknesses, textures, and designs to accommodate different product types, shapes, and sizes. This adaptability enhances the overall production process.

-

Noise Reduction: PU conveyor belts are inherently quieter in operation compared to traditional conveyor belt materials. This contributes to a more comfortable working environment for employees and a reduction in noise pollution within the facility.

Applications of PU Conveyor Belts

The versatility of PU conveyor belts makes them suitable for various stages of food production, including:

-

Sorting and Inspection: PU belts allow for gentle handling of delicate products during sorting and quality control processes, reducing the risk of damage.

-

Processing and Cooking: In food processing and cooking, where temperature fluctuations and exposure to moisture are common, PU belts maintain their integrity, ensuring continuous and reliable performance.

-

Packaging and Distribution: The customizable nature of PU belts makes them ideal for smoothly moving packaged food items through labeling, sealing, and boxing processes.

-

Freezing and Cooling: PU belts withstand low temperatures, making them suitable for applications involving freezing and cooling, such as in the production of frozen foods.

In an industry where consumer safety, efficiency, and quality are non-negotiable, PU conveyor belts have emerged as an indispensable solution. Their ability to ensure impeccable hygiene standards, reduce contamination risks, and maintain the integrity of food products sets them apart as a revolutionary technology. As the food industry continues to evolve, PU conveyor belts are poised to play a pivotal role in shaping the future of production processes, enhancing both productivity and consumer confidence.