High speed ring rubber high strength textile machinery nylon sheet base belt

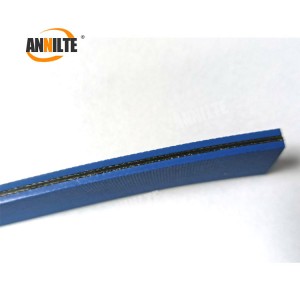

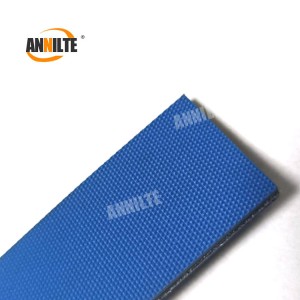

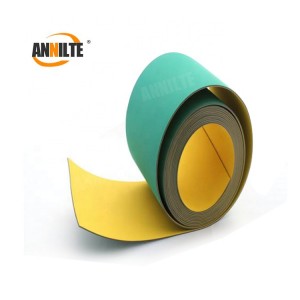

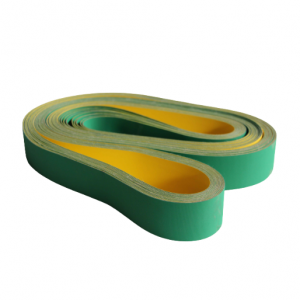

Sheet base belt (also called sheet base conveyor belt) is a kind of high-performance plane high-speed transmission belt, which is widely used in the mechanical transmission and material conveying link in the textile industry. Its core structure is supported by a high-strength nylon sheet base layer, covered with wear-resistant materials such as rubber, cowhide or fiber cloth, which has the characteristics of high tensile strength, flexing resistance, low noise and long service life, and is especially suitable for the textile industry's needs of high-speed, high-load and precision transmission.

Our Product Advantages

High-strength support: Adopting high-modulus nylon material, the tensile strength is increased by 30%-50% compared with the traditional belts, which can withstand the high impact of high loads under the high-speed operation of textile machinery.

Wear-resistant surface treatment: The surface is covered with wear-resistant rubber, cowhide or fiber cloth, which has a stable friction coefficient and extends the service life by 2-3 times.

Low noise and vibration damping: the flexible design of the sheet base belt can absorb vibration and reduce equipment noise by 10-15 dB, improving the workshop environment.

Customized service: thickness (0.8-6mm), width, surface material (such as anti-static rubber) can be customized on demand.

Product Categories

Tangential drive

Equipment type: Vapor flow spinning machine, double twisting machine, elasticizing machine, pile twisting machine, blowing and suction machine, etc.

Function: Realize high-speed power transmission between equipments through the chip base belt to ensure the continuity and stability of yarn processing.

Parallel or double-sided drive

Equipment type: carding machine, roving machine, spinning machine, drawing-in machine, circular knitting machine, etc.

Function: Utilizing the parallel drive characteristics of the sheet base belt, synchronously drive multiple working parts to enhance production efficiency.

Overload or cross drive

Equipment type: Single/double sided chrome leather (cowhide) drive flat belts.

Function: In complex drive paths, the sheet base belt withstands overload impacts by means of a high-strength material structure, minimizing drive failures.

Weaving machine sling with parallel drive

Equipment type: Loom sling system.

Function: The flexible drive of the webbing reduces mechanical vibrations and ensures smooth weaving machine operation.

Material transportation

Equipment type: Conveyor belts for textile raw materials, semi-finished products and finished products.

Function: Utilizing the wear-resistant surface of the sheet base belt, efficient and low-wear material transfer is realized.

Applicable Scenarios

Tangential drive: suitable for high speed equipment such as double twisting machine, elasticizing machine, etc., with transmission efficiency of more than 98%.

Parallel drive: synchronized drive of multiple parts in carding and roving machines, deviation rate <0.1mm.

Material conveying: anti-slip surface design ensures stable transmission of textile raw materials and semi-finished products, avoiding slipping or jamming.

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/