High Temperature Resistant Felt Belt for Ironing Machine

Rotary ironing table felt belt in the joint process, temperature resistance, air permeability and anti-running are better than ordinary felt belt. For curtain processors, choosing a high-quality rotary ironing table felt belt not only improves production efficiency, but also ensures product quality. Therefore, it is recommended that manufacturers must consider carefully when choosing a felt belt to avoid the quality of the felt belt affecting the efficiency of curtain ironing.

Product Advantages

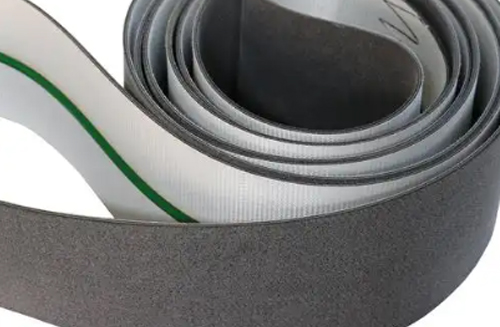

Strong joints

Joints with third-generation special technology

German superconducting vulcanization technology

83% stronger, anti-breakage

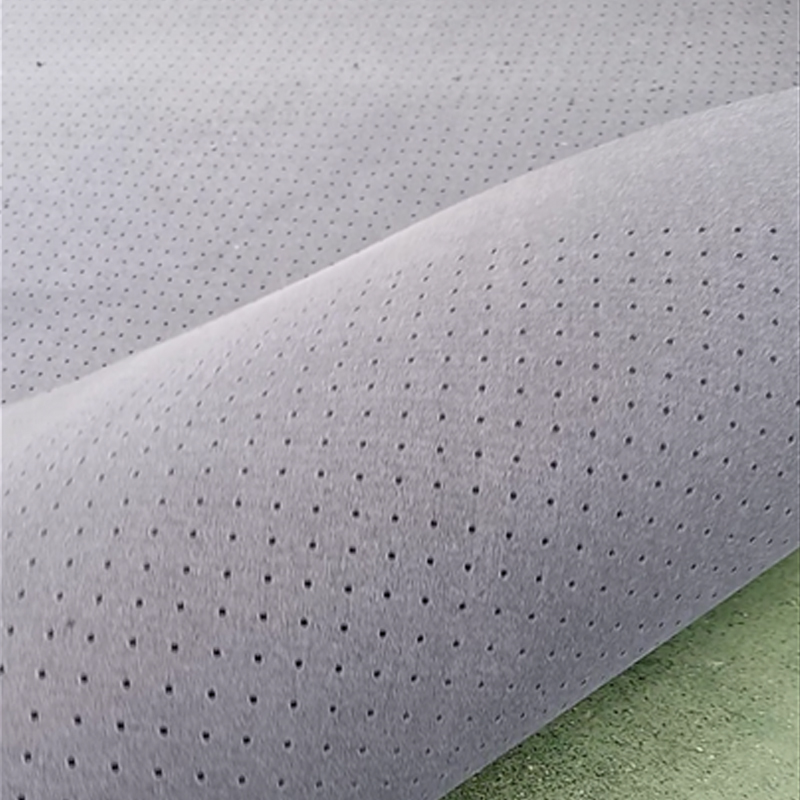

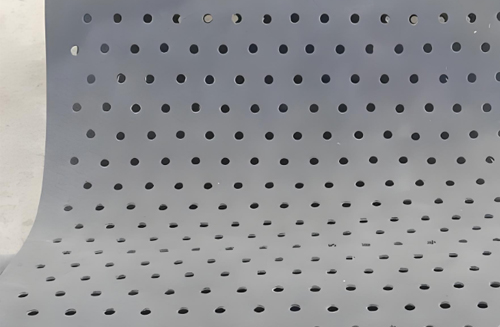

Good air permeability

CNC laser punched holes, precise hole spacing

Air permeability increased by 58%

Greatly improve the adsorption effect

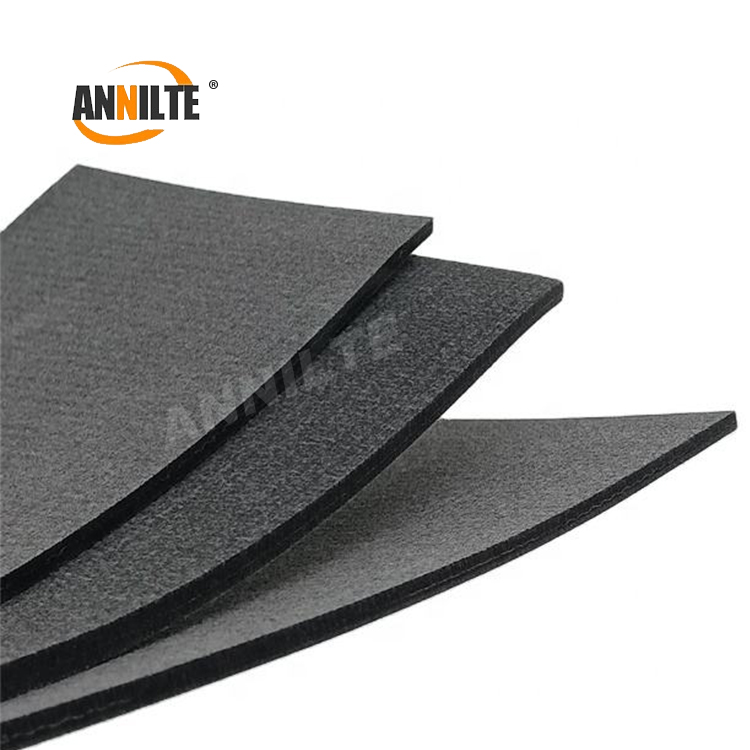

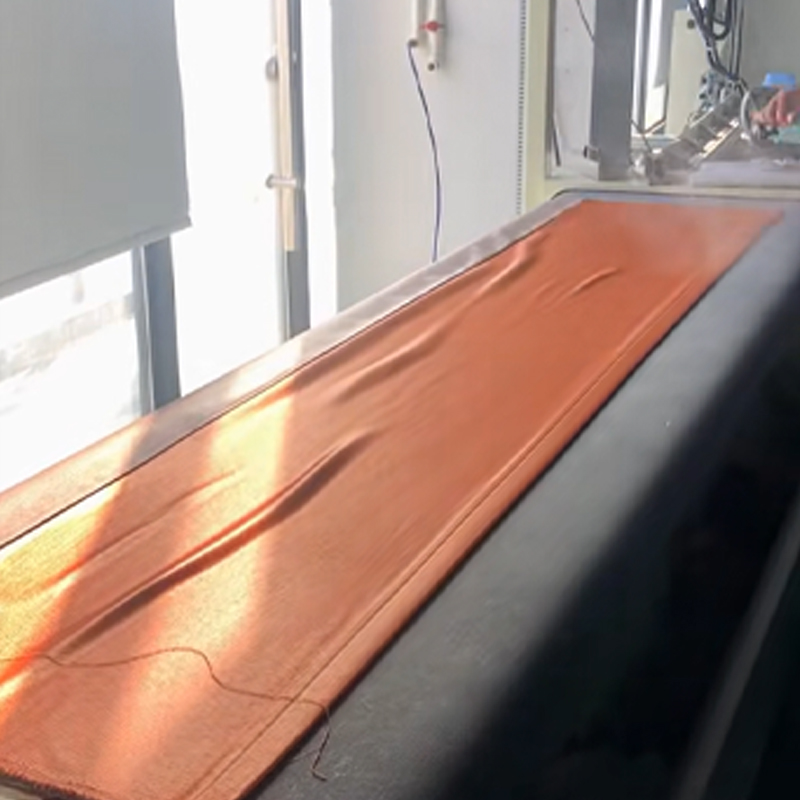

High-quality raw materials

Imported high temperature thin felt

Uniform and soft density

Prevent deflection

Guide bar, infrared positioning

Diagonal cutting without deflection

Product Process

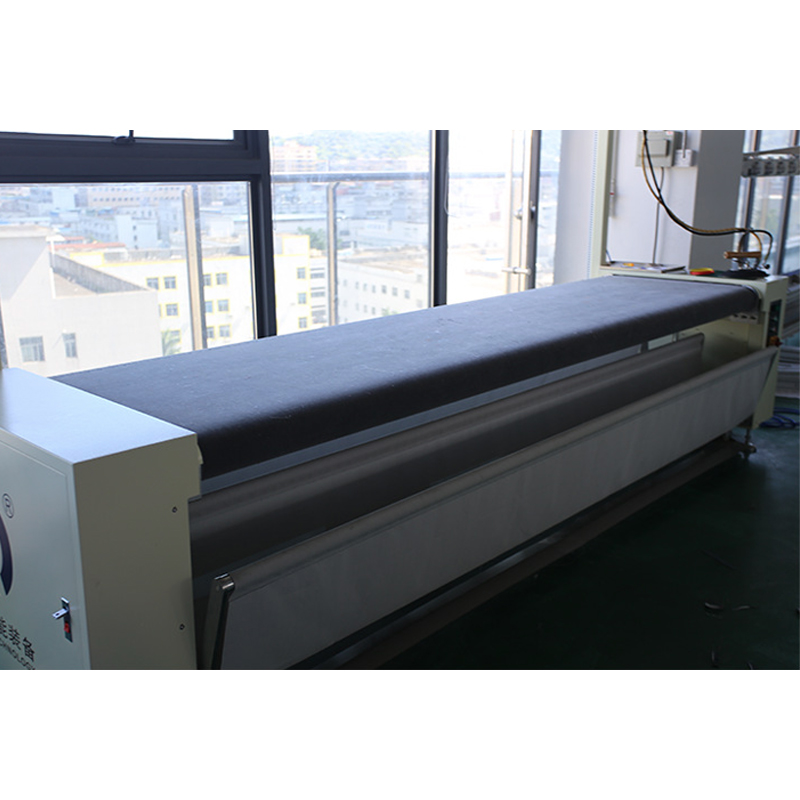

The processing of felts includes the steps of adding guides and punching holes. The purpose of adding guides is to enhance the durability and stability of the felt and to ensure that it will not be deformed or deflected in the course of use. The holes are punched for precise positioning, air absorption and ventilation.

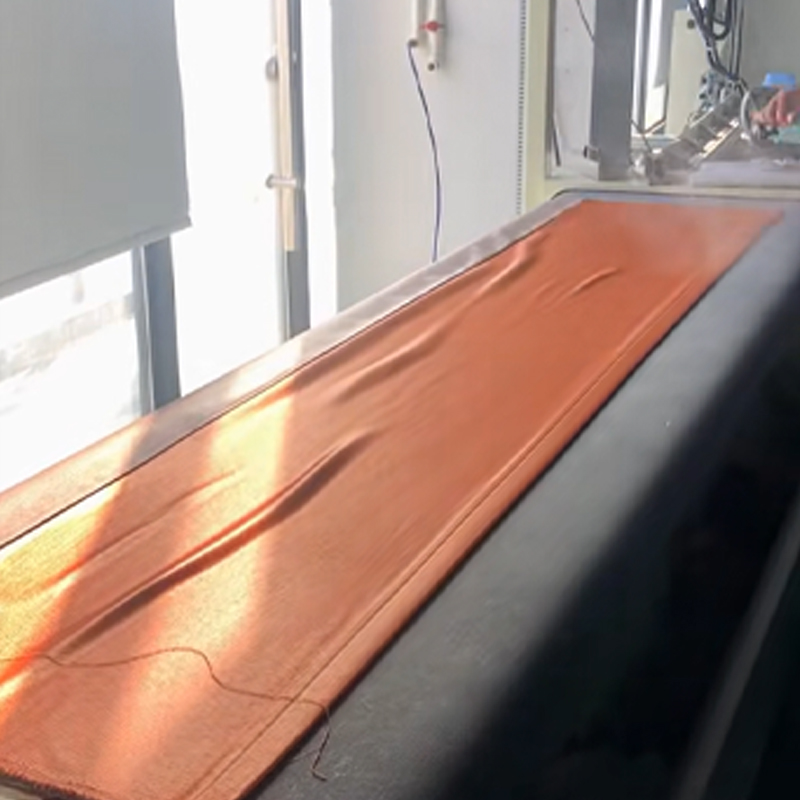

Felt Belt Perforation

Add Guide Bar

Applicable Scenarios

Widely used in curtain processing plants, curtain soft furnishing, fabric soft furnishing and other industries

Curtain Processing Plants

Fabric Soft Furnishing

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/