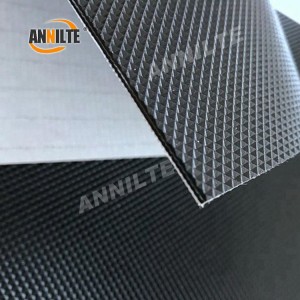

Metal Carving Board Conveyor Belt

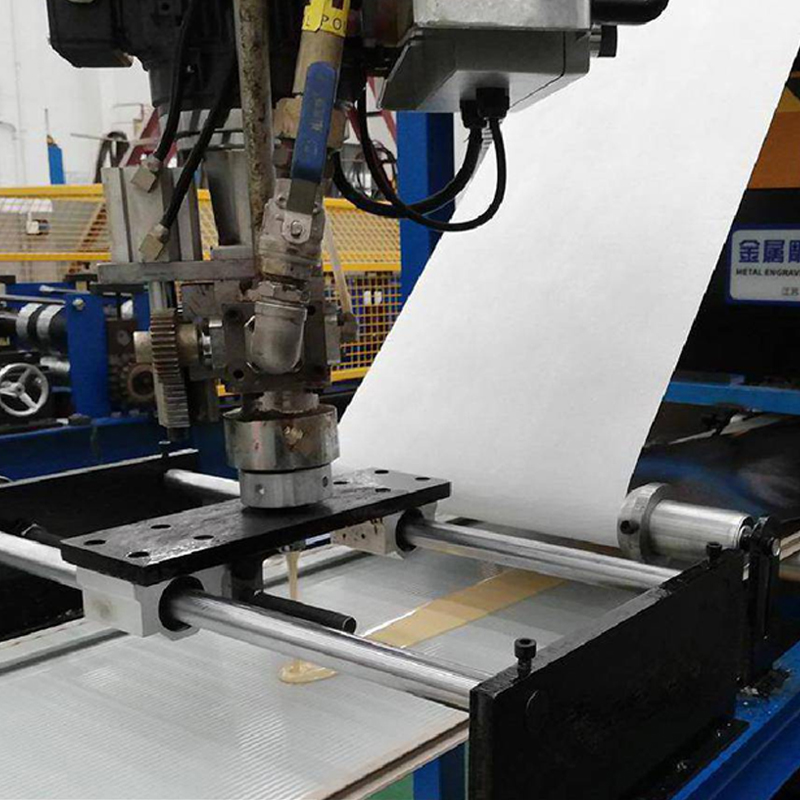

Metal Carving Board Conveyor Belt is special conveying equipment dedicated to metal engraved plate production line, mainly used for laminating process to fix the plate, control the space of styrofoam molding, which directly affects the surface flatness of engraved plate and the rate of finished products.

The Specifications of Annilte Vacuum Filter Belt

Thickness: Common thickness is 9-10mm

Weight: ≈1.56kg/㎡ per square meter.

Width: 300-2400mm (support non-standard customization)

Length: 1-10 meters standard specification (support non-standard customization)

Performance Index

Temperature resistance: 80 ℃ high temperature environment, adding polymer modified materials to prevent thermal deformation

Flatness: Tolerance ≤ 0.5mm, to avoid carving board surface reproduction defects

High hardness design: (number of cloth layers ≥ 4), to prevent extrusion deformation of styrofoam

Running stability: Adopt diagonal measurement technology, control belt deflection rate ≤2%

Our Product Advantages

High-quality conveyor belts are made of polymer temperature-resistant materials, which can keep the hardness stable under high temperature45.

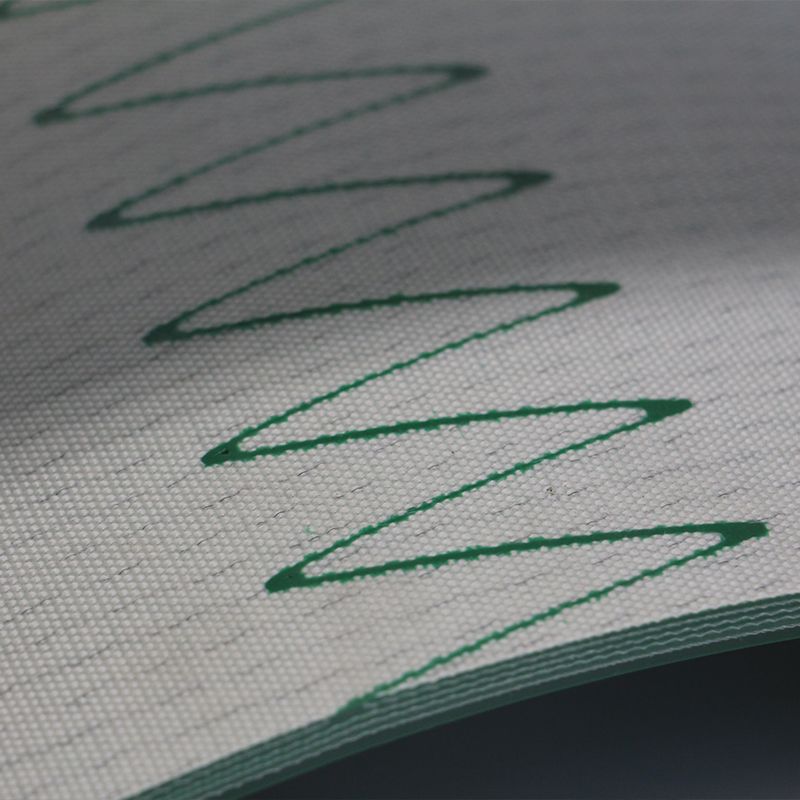

Tolerance of joints should be controlled within 0.5mm, rough joints will lead to “reproduction” defects on the surface of the engraved board, and the defective rate will increase by more than 15%

The traditional cold gluing process strip is easy to fall off, the German superconducting vulcanization technology should be used to achieve the strip and the bottom tape molding, the firmness is increased by 20%

The wear resistance of conveyor belts mixed with recycled materials is poor, and the service life is shortened by 30%-50%; the service life of belts made of virgin materials can be extended to more than 2 years.

Applicable Scenarios

Architectural field: widely used in the lamination link of metal engraved panel production line, suitable for apartment houses, old buildings remodeling and other scenarios, directly affecting the decorative effect and durability of the panel

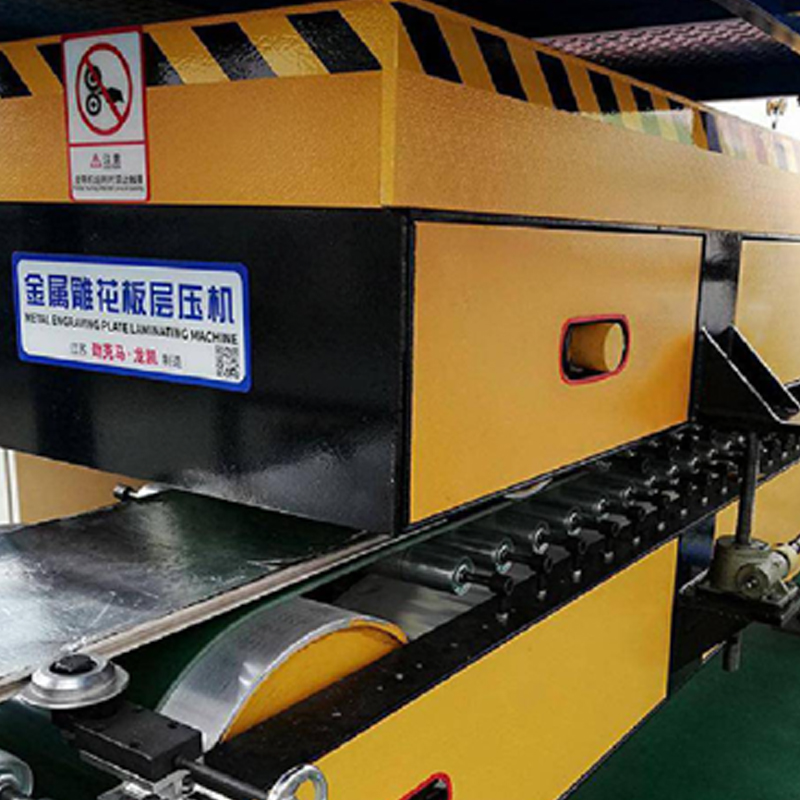

Metal carving plate production line

Metal carving plate production line

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.