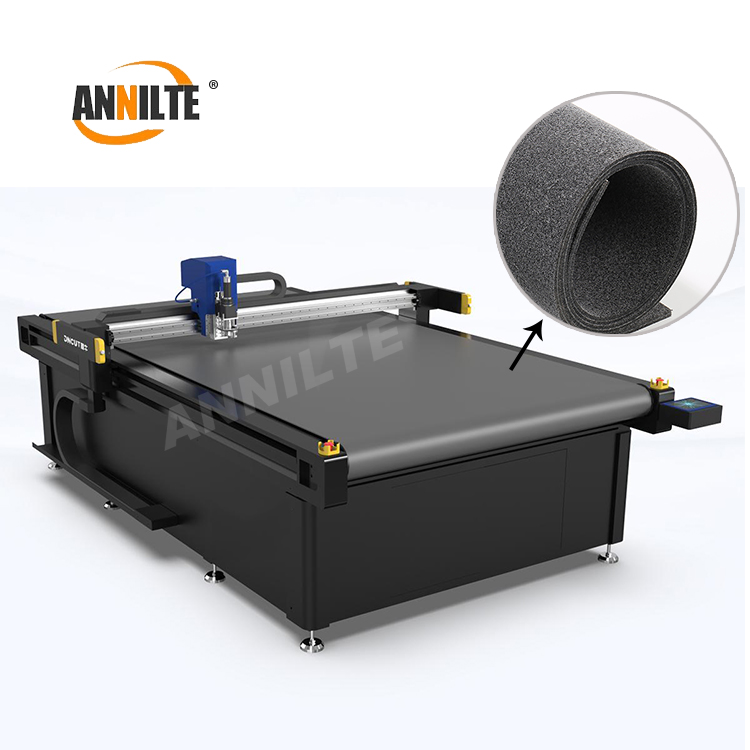

Cutting machine belts are critical components that keep your machine running smoothly, and their performance directly affects cutting accuracy and efficiency. The following signs indicate that the felt belt may be approaching the end of its useful life and needs to be replaced:

1. Heavy wear or cracks on the surface

Signs: Visible signs of wear, linting, delamination or cracking on the belt surface.

Effects: Wear causes uneven belt thickness, reducing friction and cutting stability.

Recommendation: Inspect the felt belt surface regularly and replace it immediately when severe wear is detected.

2. Deterioration of cutting accuracy

Signs: Burrs, irregularities or dimensional deviations on cutting edges.

Impact: The elasticity of the felt belt decreases after aging, and it cannot fix the material effectively, resulting in cutting deviation.

Suggestion: If the accuracy cannot be improved after adjusting the parameters of the equipment, the condition of the felt belt should be checked.

3. Abnormal noise or vibration during operation

Signs: Harsh noise or obvious vibration when the cutting machine is running.

Impact: Loose or deformed felt belts will lead to unstable transmission and increase the wear of the equipment.

Suggestion: Check the tension of the felt belt, if it is still abnormal after adjustment, the felt belt should be replaced.

4. Felt Belt Slipping or Shifting

Signs: The felt belt deviates from the track or slips on the contact surface with the material during operation.

Impact: Slipping will reduce cutting efficiency, and offsetting may lead to equipment failure or safety accidents.

Suggestion: Check the fit between the felt belt and the rollers, if it cannot be solved by adjustment, the felt belt needs to be replaced.

5. Felt belt hardens or loses elasticity

Signs: The felt belt becomes hard to the touch and does not return to its original shape after bending.

Impact: Hardening of the felt belt will cause the belt to be unable to cushion the vibration effectively and accelerate the wear and tear of the equipment.

Suggestion: Check the elasticity of the felt belt regularly and replace it in time if it is hardened.

Cutting machine felt belt is a consumable product, need to be regularly checked according to the frequency of use and working conditions. If any of the above signs occur, it is recommended to replace the felt belt immediately to avoid small losses, affecting productivity and equipment life.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Apr-24-2025