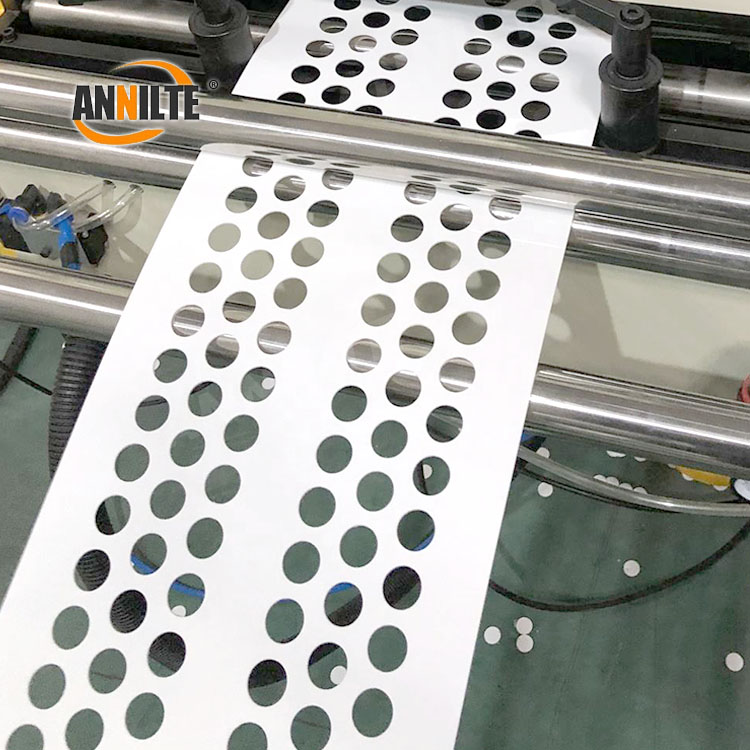

Perforated egg belts are specialized conveyor belts designed specifically for the transportation and handling of eggs in poultry processing. These belts have numerous advantages that make them particularly suitable for this purpose. Here are the key benefits of using perforated egg belts:

1. Air Circulation

- Increased Ventilation: The perforations in the belt allow for improved air circulation around the eggs, which helps maintain optimal temperature and humidity levels during transport, reducing the risk of spoilage.

2. Reduced Risk of Damage

- Gentle Handling: The design of perforated belts helps to minimize egg movement and reduce the risk of breakage. The perforated holes can provide a cushioned support that cradles the eggs without excess pressure.

3. Efficient Drainage

- Moisture Management: In environments where eggs may be washed or exposed to moisture, the perforations allow for efficient drainage, preventing water from pooling and reducing the likelihood of bacterial growth.

4. Easy Cleaning

- Maintenance: The perforated features make cleaning the conveyor belt easier, helping to maintain hygiene standards. This is particularly important in poultry processing where sanitation is crucial.

5. Lightweight Design

- Reduced Load: Perforated belts are often lighter than solid belts, which can help lower the energy consumption of the conveyor system and reduce wear on the drive components.

6. Versatility

- Multi-Use Applications: Beyond egg handling, the perforated design can be utilized in other applications where drainage and air circulation are beneficial, making these belts adaptable for various types of poultry and food processing.

7. Customizable Sizes and Designs

- Belt Specifications: Perforated egg belts can be tailored in terms of size, hole patterns, and configurations for specific processing lines, accommodating different types of eggs and production needs.

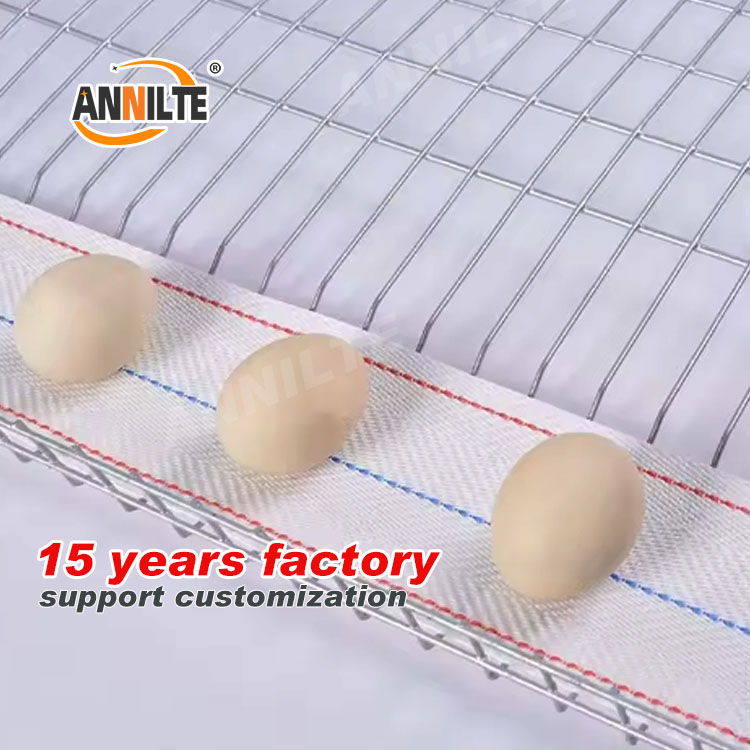

8. Enhanced Safety

- Reduced Slippage: The design helps prevent eggs from rolling or slipping during transport, enhancing operational safety and decreasing the risk of accidents.

9. Durability

- Material Strength: These belts are often constructed from durable materials that can withstand harsh processing environments while maintaining their structural integrity over time.

10. Efficient Transport

- Smooth Operation: The design of perforated egg belts facilitates a smooth and continuous flow in production lines, enhancing overall efficiency in the processing of eggs.

11. Support for Automated Systems

- Compatibility: Perforated egg belts can be integrated into automated systems, allowing for continuous or batch processing, which increases efficiency in egg collection, sorting, and packaging.

Conclusion

Perforated egg belts offer several advantages that enhance the efficiency, safety, and hygienic handling of eggs in poultry processing. Their design not only aids in protecting the eggs during transport but also contributes to the overall effectiveness and sustainability of processing operations. Choosing the right conveyor system, including perforated belts, is essential for optimizing workflow and maintaining product quality in the poultry industry.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, “ANNILTE.”

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp/WeChat: +86 185 6019 6101

Tel/WeChat: +86 18560102292

E-mail: 391886440@qq.com

Website: https://www.annilte.net/

Post time: Nov-18-2024