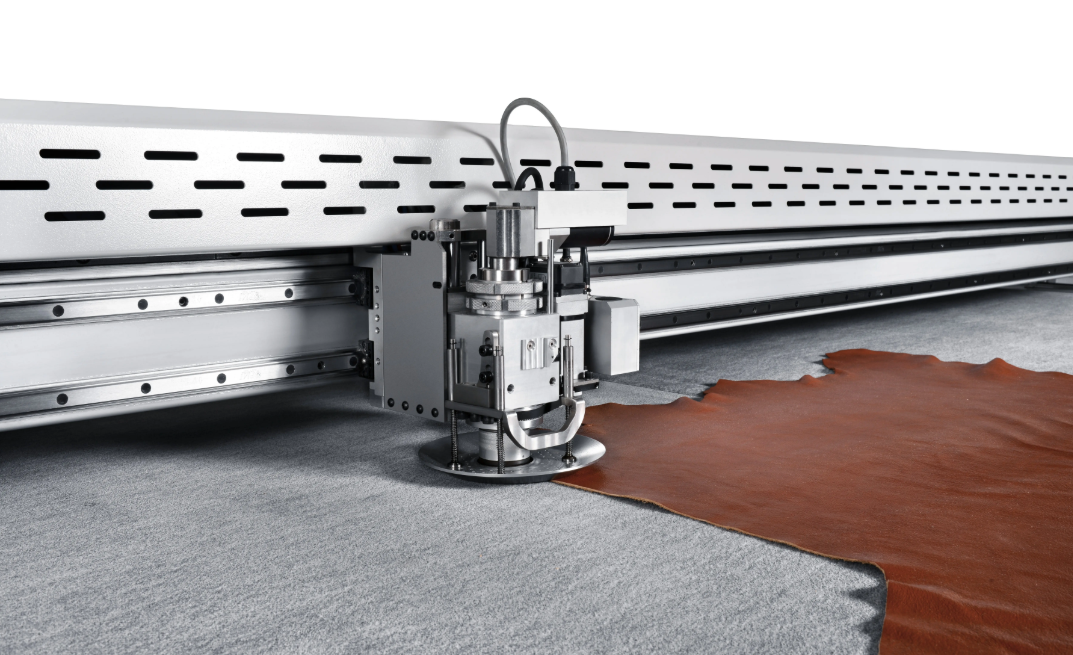

Conveyor belts used in leather cutting machines need to have good cutting resistance to adapt to frequent cutting operations.

Cut-resistant performance: high-quality cut-resistant conveyor belt should be added with polymer composite material to enhance the cut-resistant coefficient, in order to minimize the cracking and breaking problems in use.

Hardness selection: different materials require different hardness of conveyor belt, common 75 degrees, 85 degrees, 92 degrees three models, choose the right hardness can avoid quality problems in use.

Joint technology: Joint is the weakest position of conveyor belt, adopting advanced joint technology such as German superconducting vulcanization technology can improve the firmness of joint and the stability of operation.

Material: Common materials for cut-resistant conveyor belts include PU, felt, etc. These materials have better cut-resistant performance and resilience.

Customized service: Many manufacturers provide customized service, which can customize conveyor belts with different thickness, width and length according to specific needs.

Application Scenario: Cut-resistant conveyor belts are widely used in the cutting process of leather, textile, shoe insoles, plastic, paper and other materials.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, “ANNILTE.”

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp/WeChat: +86 185 6019 6101

Tel/WeChat: +86 18560102292

E-mail: 391886440@qq.com

Website: https://www.annilte.net/

Post time: Dec-16-2024