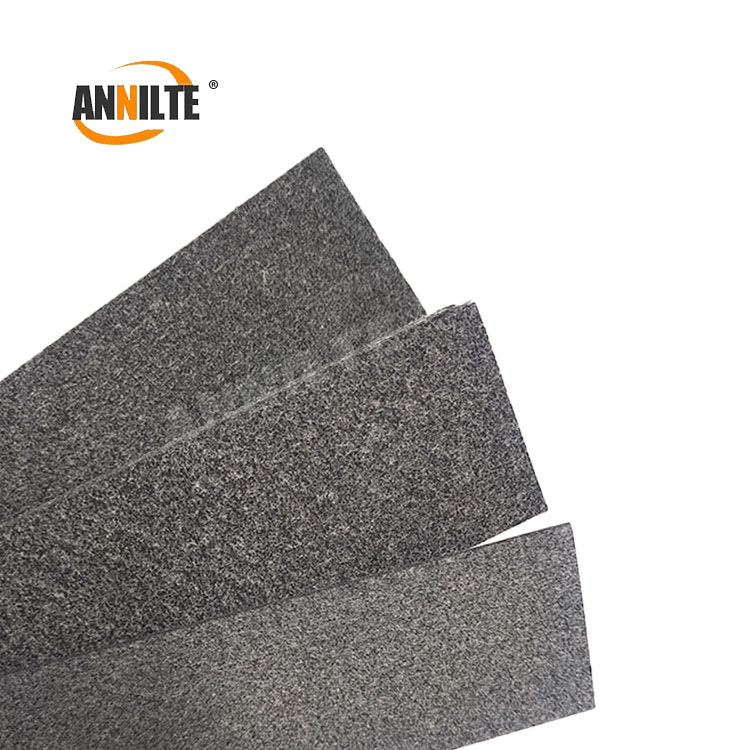

Felt belts for glass conveying have a number of significant features that make them particularly suitable for glass conveying processes. The following are some of the main features:

High Temperature Resistance: Felt belts are usually high temperature resistant and are able to operate stably in high temperature environments, ensuring safe and stable glass conveying.

Abrasion Resistance: During the glass conveying process, felt belts are subjected to constant friction and abrasion. Therefore, abrasion resistance is an important feature of the felt belt, which can ensure the durability of the conveyor belt.

Flexibility: The soft surface of the felt belt will not damage the surface of the glass, which ensures the integrity of the glass in the conveying process.

Good compatibility: Felt belts work well with the conveyor system to ensure stable glass transfer.

Strong adaptability: Felt belts are suitable for conveying glass of different sizes and shapes, and can meet different production requirements.

In addition, the felt belts have properties such as good chemical stability and tensile strength, which further enhance their reliability and safety in glass conveying.

Please note that felt belts produced by different manufacturers may have different characteristics and performance, so when choosing a felt belt, you need to select it according to the specific use environment and needs. At the same time, when using felt belts, you also need to pay attention to the maintenance and care, in order to extend its service life and improve the effectiveness of use.

Post time: Mar-18-2024