Tailings Screening Felt Belt is designed based on Bygnor's theory and the principle of fluid film beneficiation, through the action of compound force field (gravity, centrifugal force, friction, etc.), the mineral particles form a fluid film layer on the surface of the felt. Mineral particles of different densities are stratified in the flow film, high-density minerals are retained by the felt, and low-density minerals are discharged with the water flow, thus realizing the recovery of metal minerals in the tailings.

High-quality raw materials and efficient beneficiation

Adopting imported needle felted wool as raw material, the felt is highly absorbent and hydrophobic, which can firmly hang on the ore powder and is not easy to be deformed. The advanced needle felting process improves the fluffiness of the felt, which enhances the effect of ore retention, and the beneficiation rate can be increased by more than 70%.

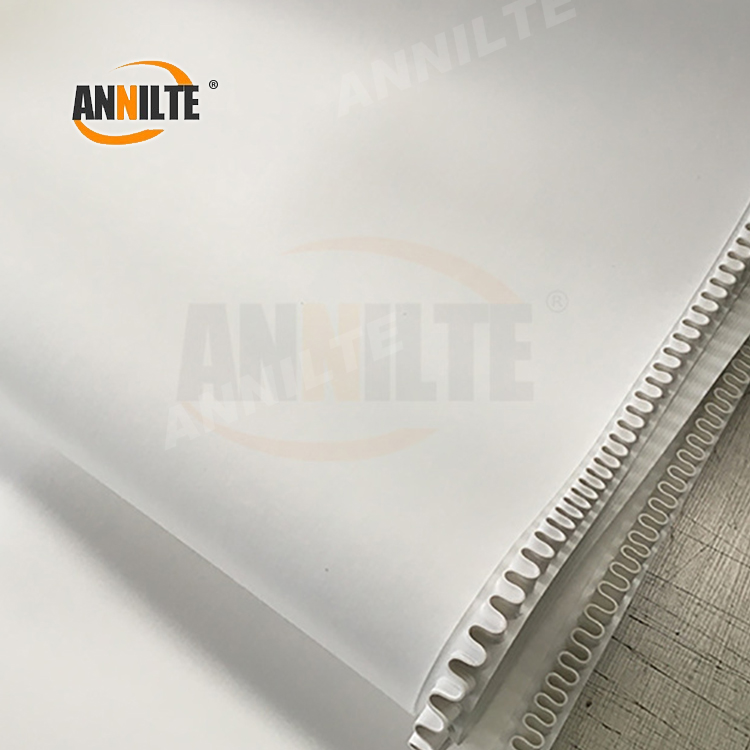

Seamless skirt design

The combination of seamless skirt and specific slow S curvature ensures that the conveyor belt does not hide, leak, or run materials in use, and the materials are conveyed stably and efficiently.

Durability and long life

The bottom belt is made of virgin rubber imported from Holland, with good flexibility, anti-aging, hydrolysis resistance, excellent flexing, and significantly longer service life. The felt can be activated and reused twice to further reduce the cost.

High softness and precise screening

The high softness of the felt is conducive to the screening of non-ferrous metals, filtering out impurities such as sand and silt, and improving the screening precision.

Advanced technology and structure optimization

Seamless edge design improves the screening effect by more than 50%; the joint adopts automatic temperature control system, which makes it smooth and beautiful; infrared diagonal measurement technology ensures smooth operation without deviation.

Wide range of application

It is applicable to the beneficiation process of gold, tungsten, tin, molybdenum, iron, copper, manganese, lead and other non-ferrous metals, as well as the screening of molybdenum and iron, tungsten and tin, tantalum and niobium, titanium, nickel and other minerals.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Apr-08-2025