Teflon mesh belt is a high-performance, multi-purpose composite material new products, its main raw material is polytetrafluoroethylene (commonly known as Plastic King) emulsion, through the impregnation of high-performance fiberglass mesh and become. The following is a detailed introduction of Teflon mesh belt:

Main features

Temperature resistance: Teflon mesh belt can work stably between low temperature -70℃ and high temperature 260℃, with excellent weather resistance and anti-aging properties. It has been verified by practical application that its strength and weight do not change significantly when placed continuously for 200 days at a high temperature of 250℃.

Non-adhesion: the surface of the mesh belt is not easy to adhere to any substance, easy to clean all kinds of oil stains, stains or other attachments attached to its surface. Almost all adhesive substances such as paste, resin, paint, etc. can be simply removed.

Chemical resistance: Teflon mesh belt is resistant to strong acids, alkalis, aqua regia and various organic solvents, showing excellent chemical stability.

Dimensional Stability and Strength: The mesh belts have good dimensional stability (elongation coefficient less than 5‰) and high strength, which ensures their reliability and durability in a variety of applications.

Other characteristics: It also includes resistance to bending fatigue, pharmaceutical resistance, non-toxicity, fire retardant, good air permeability and other characteristics. These characteristics make Teflon mesh belt widely used in many industrial fields.

Application Scope

Teflon mesh belt is widely used in the following fields because of its excellent performance:

Textile, printing and dyeing: such as printing drying, bleaching and dyeing fabric drying, fabric shrinkage drying, nonwoven fabric drying and other drying channel, drying room conveyor belt.

Screen, printing: such as loose drying machine, offset printing machine, UV series of light solid machine, paper over oil drying, ultraviolet drying, plastic products screen printing drying and other drying channel, drying room conveyor belt.

Other items: such as high-frequency drying, microwave drying, various types of food freezing and defrosting, baking, packaging items heat shrinkage, general moisture content of the drying of goods, rapid drying of the melt-type ink, such as drying room guide belt.

Specification

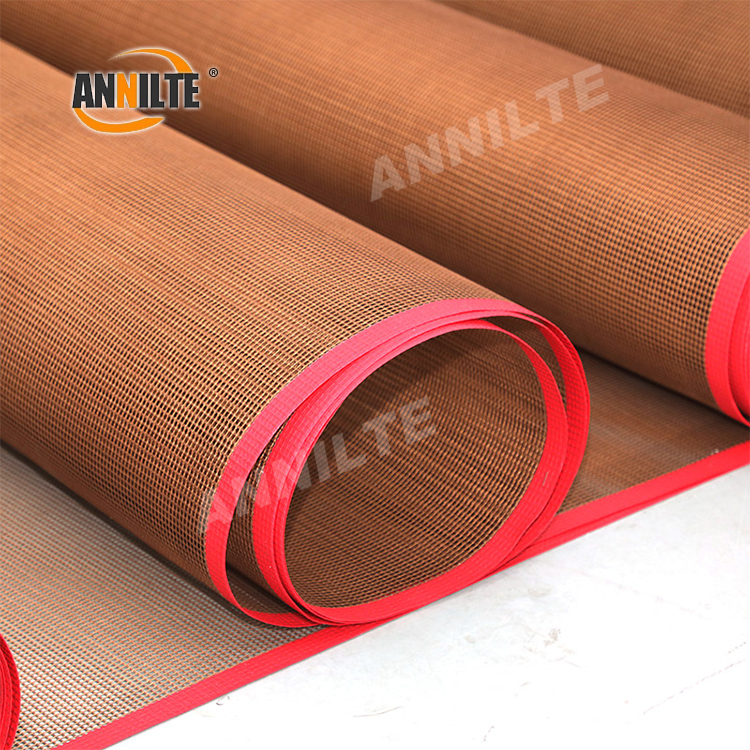

The specification parameters of Teflon mesh belt can be customized according to specific needs, generally including thickness, width, mesh size and color. The common thickness range is 0.2-1.35mm, width is 300-4200mm, mesh is 0.5-10mm (quadrilateral, such as 4x4mm, 1x1mm, etc.), and the color is mainly light brown (also known as brown) and black.

IV. Precautions

When using Teflon mesh belt, the following points should be noted to ensure its normal operation and prolong its service life:

Regularly check the tension and operation of the mesh belt for timely adjustment and maintenance.

Avoid contacting the mesh belt with sharp objects to prevent scratching.

Appropriate cleaning agents and tools should be used when cleaning to avoid damaging the surface of the mesh belt.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We customize many kinds of belts .We have our own brand “ANNILTE“

If you have any questions about the conveyor belts, please contact us!

E-mail: 391886440@qq.com

Wechat:+86 185 6010 2292

WhatsApp: +86 185 6019 6101

Website:https://www.annilte.net/

Post time: Aug-12-2024