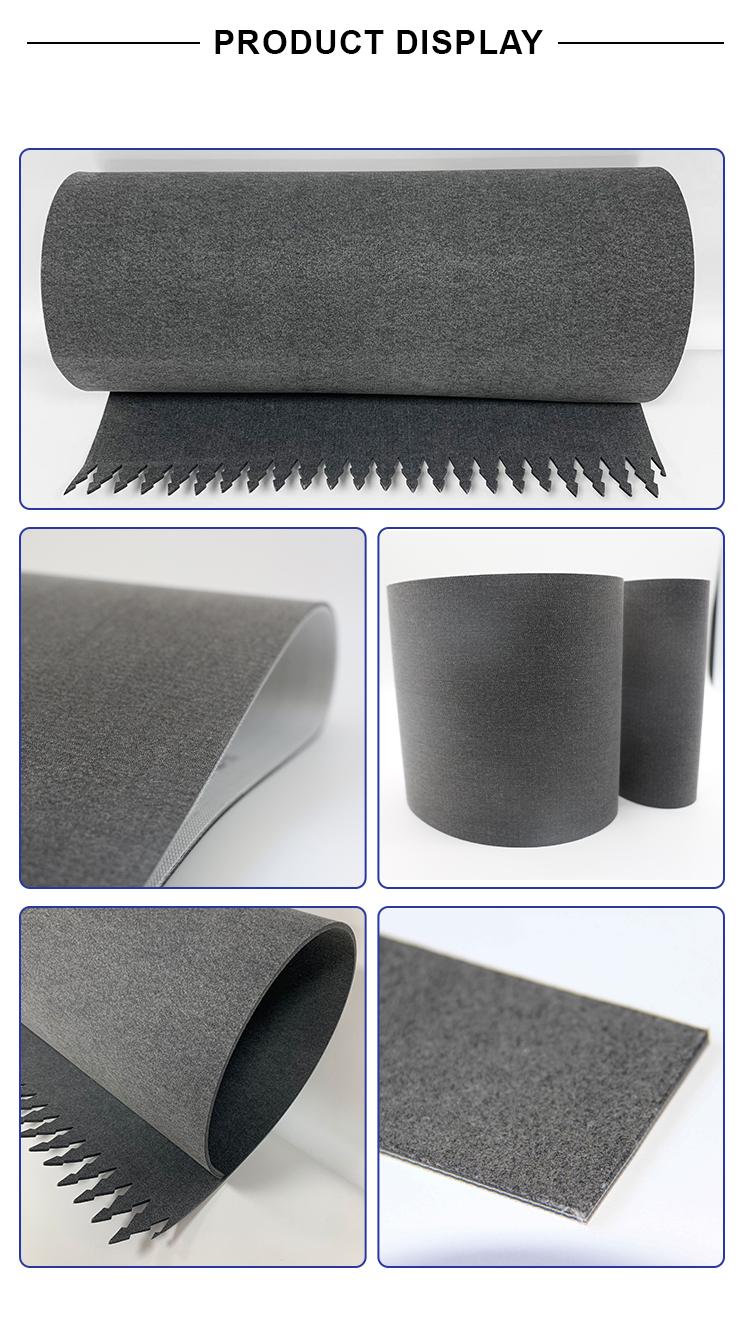

Single Side Felt Conveyor Belt: anti-static surface, wear-resistant, cut-resistant, anti-scratch, anti-scratch are mainly used in home appliance industry, steel plate conveying, electronic product conveying, etc.

Double-sided felt conveyor belt: excellent high conductivity; high tensile strength, belt elongation in the use of small, improve the stability of the belt; the surface of the use of abrasion-resistant soft material, cut-resistant to ensure that the conveyor cutting process of product flatness; high impact resistance to prevent the impact of the product brought about by the fall; breathable, wind-absorbent, to prevent the product is too light to flutter up in the conveyor process.

The double-sided felt conveyor belt is used in cutting machines, automatic soft cutting machines, CNC soft cutting machines, logistics transportation, metal plate, casting transportation, etc.

Thickness of double-sided felt conveyor belt: 2.5mm, 4.0mm, 6.0mm.

High temperature felt conveyor belt: 180°C, 280°C, 500°C, 600°C.

High-temperature felt conveyor belts are mainly used in: aluminum profile resistance, die casting, etc.,.

Annilte is a manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We customize many kinds of belts .We have our own brand “ANNILTE”

If you have any questions about the conveyor belts, please contact us!

E-mail: 391886440@qq.com

Wechat:+86 185 6010 2292

WhatsApp: +86 185 6019 6101

Website:https://www.annilte.net/

Post time: Jul-18-2024