Customers have more and more demands for different conveyor belts. There are many problems in the process of use, even causing the whole production line to stop production, which is more distressing. Here is how to deal with common problems with skirt conveyor belt.

1、What if the skirt baffle conveyor belt runs out of alignment?

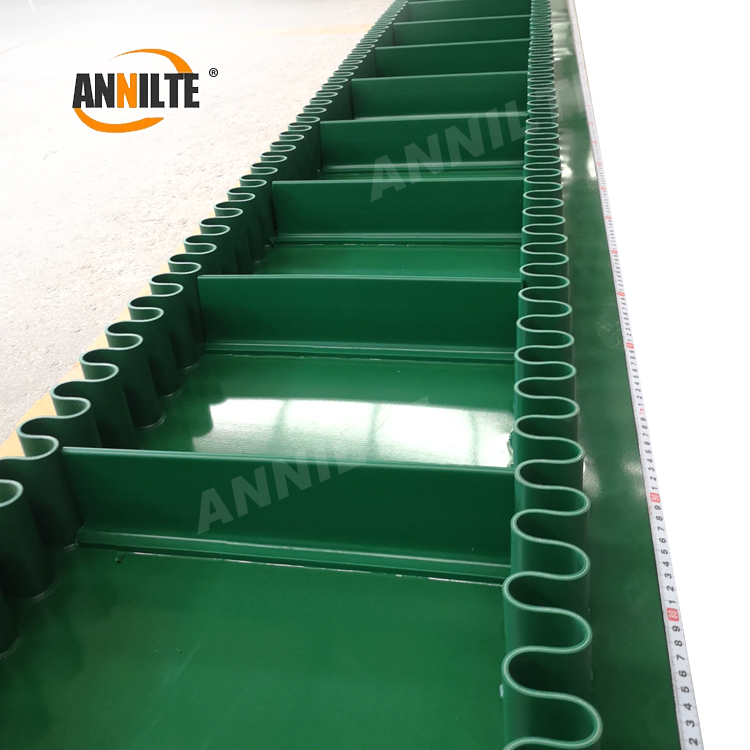

Conveyor belt runout often occurs in the production process, then, we have added the function of guiding strip to prevent runout in the production of conveyor belt. Through the guide strip auxiliary adjustment, it effectively solves the damage to the conveyor belt itself by the belt runout and prolongs the service life.

2、Shedding also often occurs in the use of conveyor belt

There are two main reasons.

① There are hard objects cutting the belt on the equipment.

Solution: stop to check the foreign body, the damaged part of the timely and abnormal hot melt rework, so as not to expand the off part to cause greater failure.

② The drum is too small, causing the belt to tear.

Solution: The general roller diameter requirement is three times the height of the skirt baffle.

Our company uses high-frequency hot fusion equipment, all skirt baffle, are precision abrasive hot fusion processing, compared with traditional manual processing, more solid, flat, beautiful.

Post time: Jan-13-2023