With the continuous development of manufacturing and construction industry, the market demand of sander industry is growing.

Especially in the metal processing industry, the sander, as a kind of high-efficiency and powerful grinding equipment, is a very important equipment, which can carry out surface treatment for metal products, including deburring, drawing, polishing, etc. It can remove the oxidation layer, rust, scratches, etc. on the metal surface, make its surface smoother and more beautiful, and improve its quality and value.

However, according to the market feedback, there are problems such as excessive competition, serious homogenisation and small profit margins for sanding machines. Therefore, in the market, enterprises need to focus on technological innovation in order to gain a competitive advantage in the market.

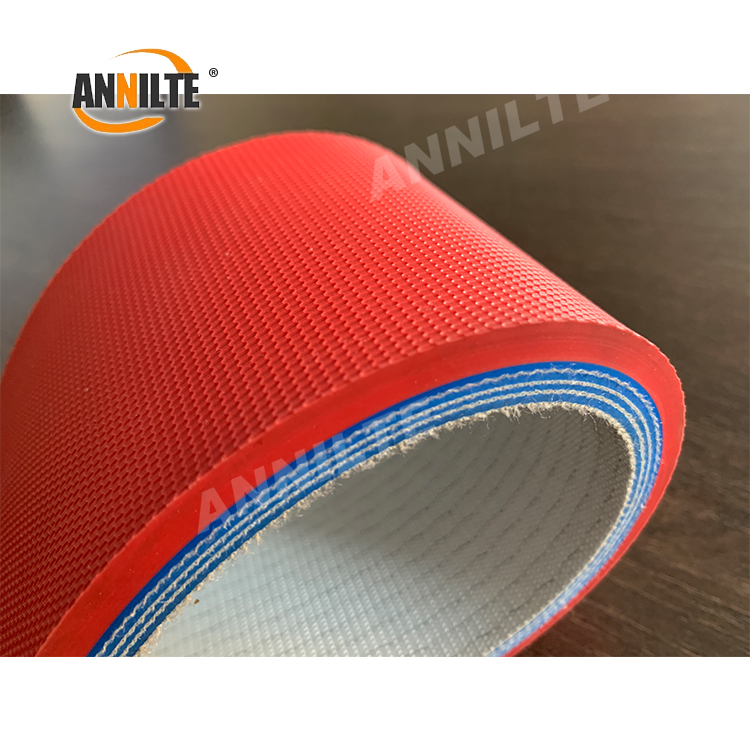

Metal sander belt is also called metal sander conveyor belt, which is an important component of metal sander equipment, mainly used to transport sanding materials. There are two kinds of common sander belts on the market: large metal sander belt and small metal sander belt.

If the belt used by the metal sander equipment company does not match the product, there will be slipping, sanding out traces and other phenomena, not only the product after-sales problems, the brand image will also be affected. So in the selection of belts should be selected and sanding machine matching high, smooth running, high efficiency conveyor belt.

Metal sander belt advantages:

(1) The rubber of the belt is very soft, tough, strong adhesion, anti-slip, good effect of polishing and deburring;

(2) Suitable for small pieces of sanding, the surface gel is soft, high damping friction, to ensure that the object will not slip in the conveyor;

(3) Suitable for large pieces of sanding sanding machine, using German superconducting vulcanisation technology, the belt joints are flat, to ensure that the objects are transported smoothly, sanding without traces.

Post time: Oct-08-2023