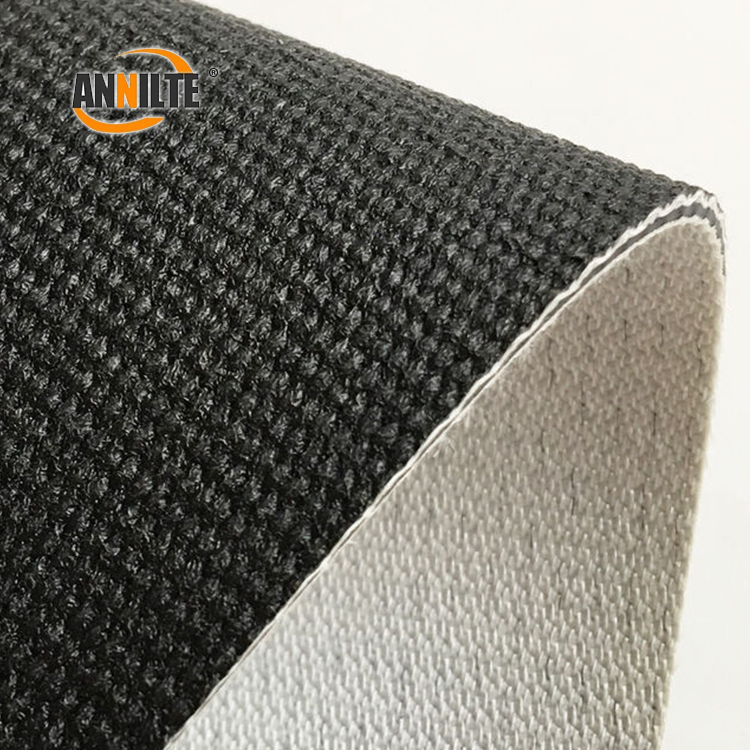

PVK logistics conveyor belt mainly refers to the conveyor belt which is produced by adopting three-dimensional weaving of the whole core fabric and by impregnating PVK slurry. This production method ensures the integrity and stability of the conveyor belt and avoids hidden problems such as delamination.

1、Features and Advantages

High abrasion and cut resistance: PVK conveyor belts have higher abrasion and cut resistance compared with ordinary PVC conveyor belts, and their service life can be extended by 3-4 times. This means that PVK conveyor belts are able to withstand more friction and impact during the logistics sorting process, reducing the frequency of damage and replacement, thus improving overall operational efficiency.

A variety of excellent characteristics: PVK conveyor belts are also smash-resistant, flame retardant, moisture-proof, anti-static, high tensile strength, corrosion-resistant, low ductility, strong adhesion, and non-shedding. These characteristics make PVK conveyor belts adaptable to various complex and harsh logistics environments, ensuring the safety and stability of goods in the sorting process.

Low noise effect: PVK conveyor belts produce low noise during operation, which helps to improve the working environment and protect the hearing health of employees.

Anti-skid performance: The surface of PVK material is rough, which helps to increase the friction and is suitable for dealing with materials that need higher friction, and also has certain anti-skid performance.

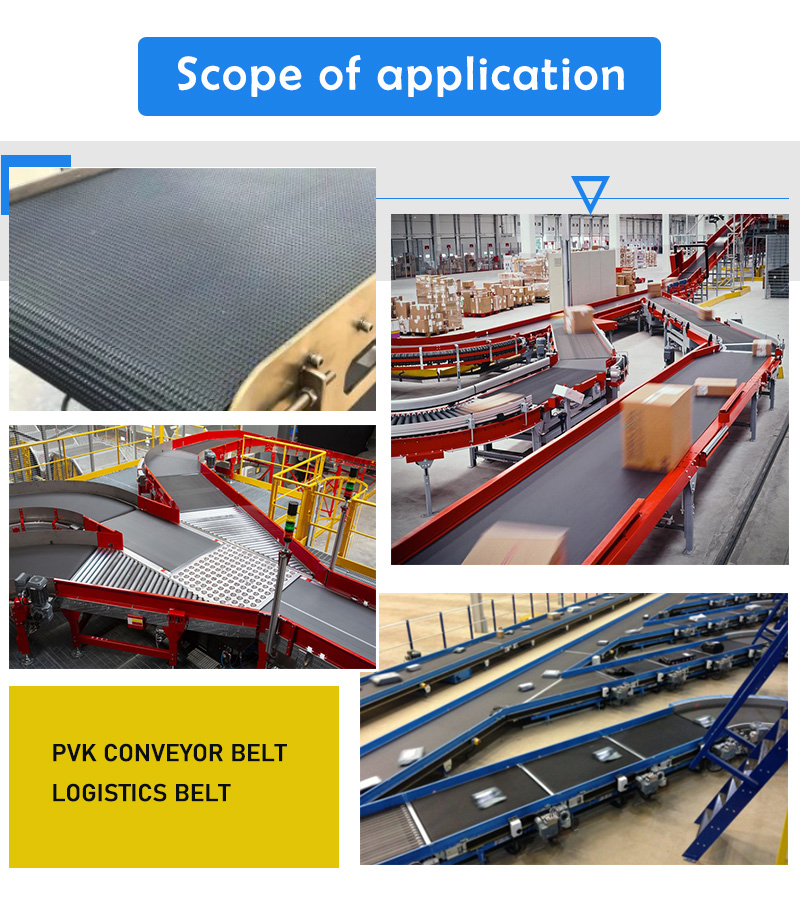

2、Application Scenario

Airport Conveyor Belt: Due to its high abrasion resistance, cutting resistance and anti-slip properties, PVK logistics conveyor belt is often used in airport baggage conveying system, such as baggage security check, baggage sorting and other links. Therefore, PVK conveyor belts are also called “airport conveyor belts”.

Logistics Sorting Conveyor Belt: In the logistics industry, PVK logistics conveyor belts are widely used in logistics sorting systems to improve the efficiency and accuracy of logistics sorting. Therefore, it is often directly referred to as “Logistics Sorting Conveyor Belt”.

Three-dimensional woven core fabric conveyor belt: PVK logistics conveyor belt adopts three-dimensional woven integral core fabric as the substrate, which is made by impregnating PVK slurry. This unique production process has led to it also being called a “three-dimensional woven core fabric conveyor belt”.

Wear-resistant conveyor belts: In view of the high abrasion resistance of PVK materials, PVK logistics conveyor belts perform well in long-time, high-intensity use, and are therefore also commonly known as “wear-resistant conveyor belts” in the market.

Logistics Sorting Belt: In the logistics warehousing and sorting process, PVK logistics conveyor belts play an important role in sorting and conveying, and are therefore also known as “Logistics Sorting Belt” by some industry players.

Annilte is a manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We customize many kinds of belts .We have our own brand “ANNILTE”

If you have any questions about the conveyor belts, please contact us!

E-mail: 391886440@qq.com

Wechat:+86 185 6010 2292

WhatsApp: +86 185 6019 6101

Website:https://www.annilte.net/

Post time: Jul-30-2024