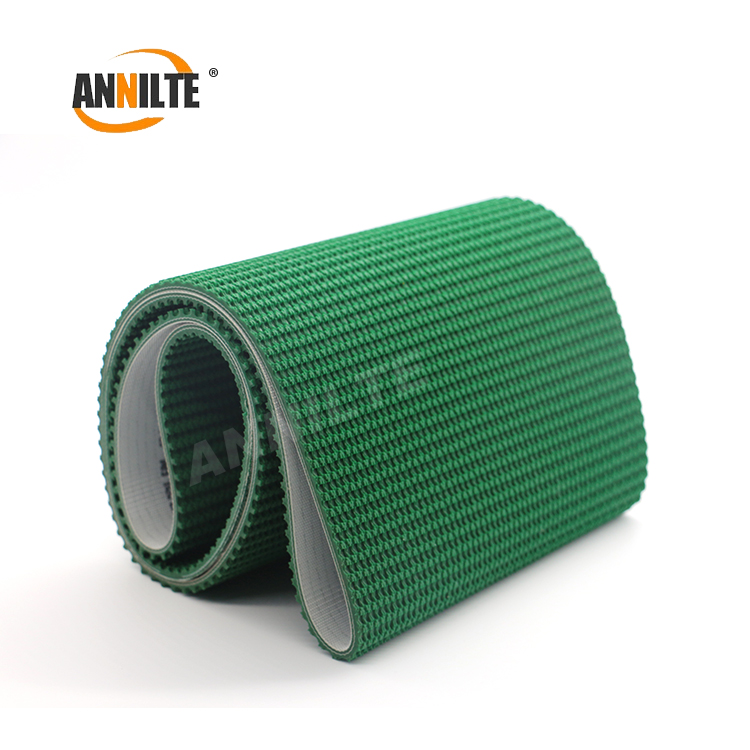

March, everything is recovering, it is the golden time to prepare for spring plowing. However, the waste film in the farmland has become a “white pollution” plaguing agricultural production. At this time, the residual film recycling machine belt as the core component of the residual film recycling machine, is playing an irreplaceable role. Through the wear-resistant pattern on the belt, it rubs up the film attached to the ground and rolls it up, which “reduces the burden” for the farmland and “opens the way” for spring plowing.

A high-quality residual film recycling machine belt is not only the guarantee of efficient recycling, but also the guardian of farmland environmental protection.

High-quality residual film recycling machine belt often has the following core advantages:

1, no deflection

residual film recycling machine belt on the back of the design of a high degree of straightness of the guide strip, combined with infrared positioning and diagonal cutting process, to ensure that the size of the accurate and stable operation. This design effectively avoids the problem of belt deflection and ensures that the equipment still operates efficiently in complex terrain.

2、Firm joints

adopts multi-layer denting process and German superconducting vulcanization technology, which significantly improves the firmness of the joints of the belt and completely eliminates the phenomenon of open teeth. This design not only prolongs the service life of the belt, but also reduces the failure rate of the equipment and ensures that the recycling work is carried out smoothly.

3, good abrasion resistance

high quality residual film recycling machine belt is made of virgin material, and add nano abrasion resistance factor, greatly improving the abrasion resistance. Even in the gravel, mud and other harsh environments, the belt can still maintain stable performance, easily cope with a variety of challenges.

4、Long service life

The belt interlayer is made of high-strength polyester fiber, which improves the tensile strength by 60% and extends the service life three times longer than ordinary conveyor belts. This design not only reduces the frequency of replacement, but also reduces the maintenance cost, ensuring the efficient promotion of residual film recycling.

A high-quality residual film recycling machine belt plays a vital role in the residual film recycling work by virtue of the advantages of no deflection, strong joints, good wear resistance, long service life and so on. It not only reduces white pollution in farmland, but also lays a solid foundation for spring plowing. If you have more questions about the residual film recycling machine belt, welcome to leave a message in the comment area to interact.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Mar-19-2025