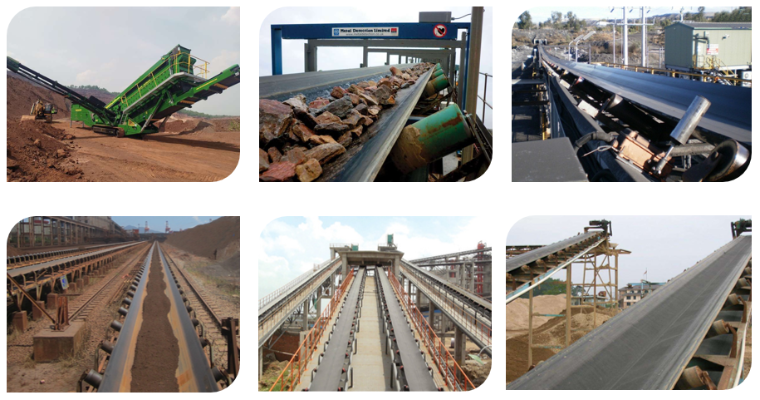

Rubber conveyor belts are mainly used in concrete batching, mixing and conveying processes to ensure that materials can be efficiently and continuously passed from one process to another. They are widely used in concrete mixing stations, cement plants and other places, and are one of the indispensable equipment in concrete batching plants.

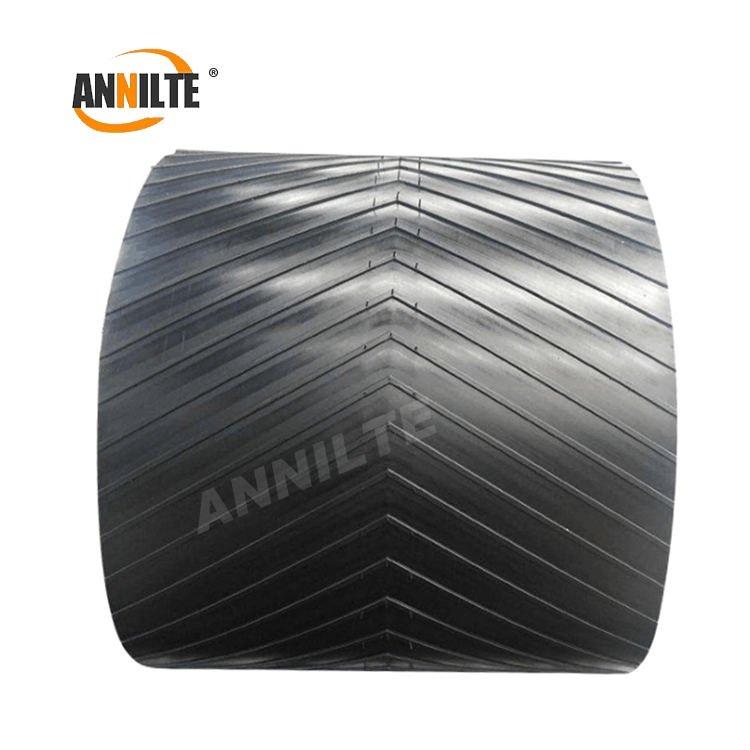

Ordinary rubber conveyor belt: the tensile strength of the cover layer is not less than 15Mpa, the elongation at break is not less than 350%, the abrasion is small, and the bonding strength between layers is high. This kind of conveyor belt is suitable for general concrete batching and conveying tasks, featuring low cost and good abrasion resistance.

Nylon (NN) and polyester (EP) conveyor belts: with higher strength and abrasion resistance, they are suitable for heavy-duty, high-speed concrete batching and conveying tasks. The tensile strength of the cover layer is also not less than 15Mpa, and the elongation at break is not less than 350%, but the bonding strength between the layers is higher, which ensures the stable operation of the conveyor belts under adverse working conditions.

Flame-retardant conveyor belts: complying with MT147-95 standard, with excellent flame-retardant performance, suitable for concrete batching plants with high requirements on fire prevention.

Anti-static conveyor belts: specially designed to prevent static build-up and ensure safety during conveying.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, “ANNILTE.”

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp/WeChat: +86 185 6019 6101

Tel/WeChat: +86 18560102292

E-mail: 391886440@qq.com

Website: https://www.annilte.net/

Post time: Dec-27-2024