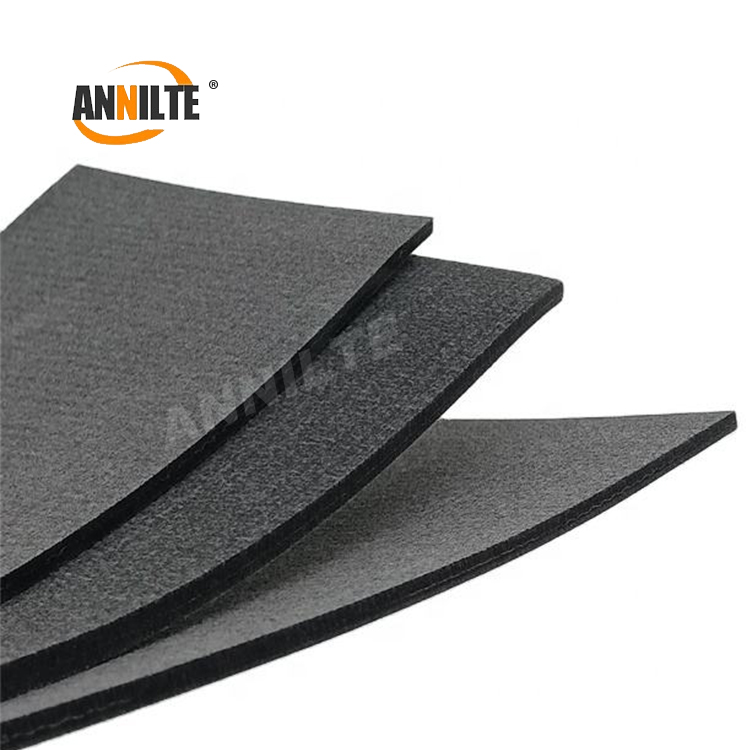

The main difference between double-sided felt conveyor belts and single-sided felt conveyor belts lies in their structural and performance characteristics.

Structural features: Double-sided felt conveyor belts consist of two layers of felt material, whereas single-sided felt conveyor belts have only one layer of felt. This makes double-sided felt conveyor belts generally higher in thickness and felt coverage than single-sided felt conveyor belts.

Load carrying capacity and stability: Because double-sided felt conveyor belts are more symmetrical in structure and more uniformly loaded, their load carrying capacity and stability are usually better than single-sided felt conveyor belts. This makes double-sided felt conveyor belts suitable for transporting heavier weights or items that require greater stability.

Abrasion resistance and service life: Double-sided felt conveyor belts are made of thicker felt material, so their abrasion resistance and service life are usually longer than single-sided felt conveyor belts. This means that double-sided felt conveyor belts maintain better performance in long, intense work environments.

Price and Replacement Costs: Because double-sided felt conveyor belts are typically more expensive to manufacture and cost more in materials than single-sided felt conveyor belts, they can be more expensive. In addition, when replacement is required, double-sided felt belts need to be replaced on both sides, which also increases replacement costs.

In summary, double-sided felt conveyor belts have advantages over single-sided felt conveyor belts in terms of construction, load carrying capacity and stability, abrasion resistance and service life, but they may be more expensive and costly to replace. The choice of conveyor belt depends on the specific application requirements and scenario.

Post time: Feb-26-2024