The problem of burring on felt conveyor belts on cutting machines can be caused by the following factors:

Quality of raw materials: Similarly, quality problems of raw materials (e.g. addition of waste and recycled materials) may cause felt conveyor belts to be furred during use.

No tensile layer: There exists a part of felt conveyor belts on the market without a tensile layer. If the tensile strength of the felt conveyor belt does not meet the requirement during the feeding process, the phenomenon of burring may occur.

In order to solve the burr problem of felt conveyor belts on cutting machines:

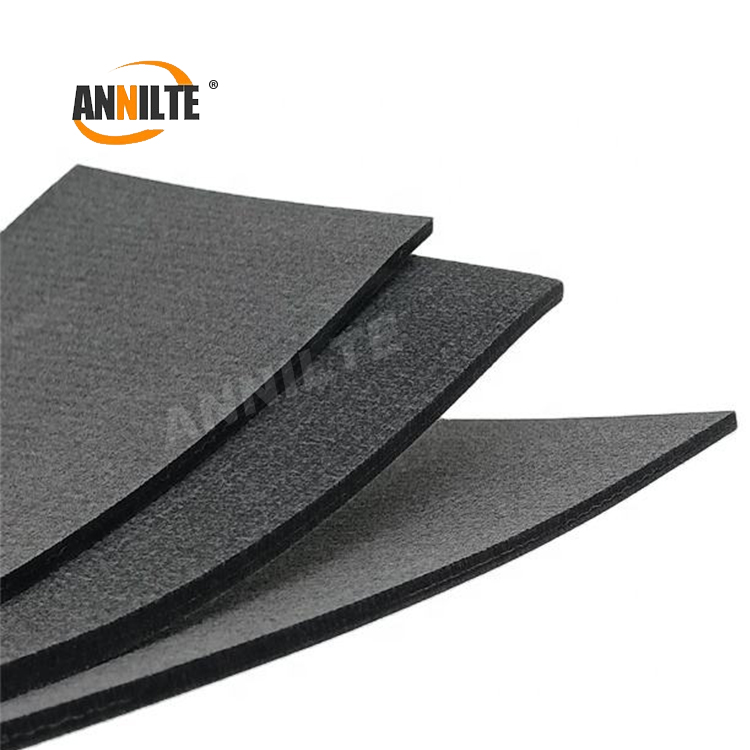

1、Select high-quality raw materials and felt conveyor belts with tensile layers.

2、Regularly inspect and maintain the cutter and felt conveyor belt to identify and deal with potential problems in a timely manner.

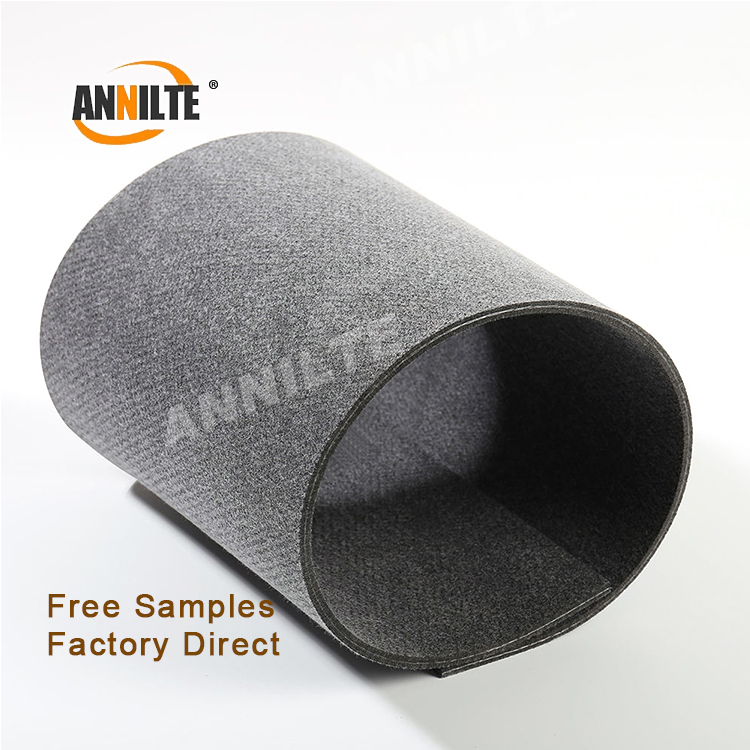

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, “ANNILTE.”

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp/WeChat: +86 185 6019 6101

Tel/WeChat: +86 18560102292

E-mail: 391886440@qq.com

Website: https://www.annilte.net/

Post time: Jan-23-2025