100% Nomex Felt Belt Conveyor Belt Endless Aramid Fiber Felt for Roller Heat Transfer Machine

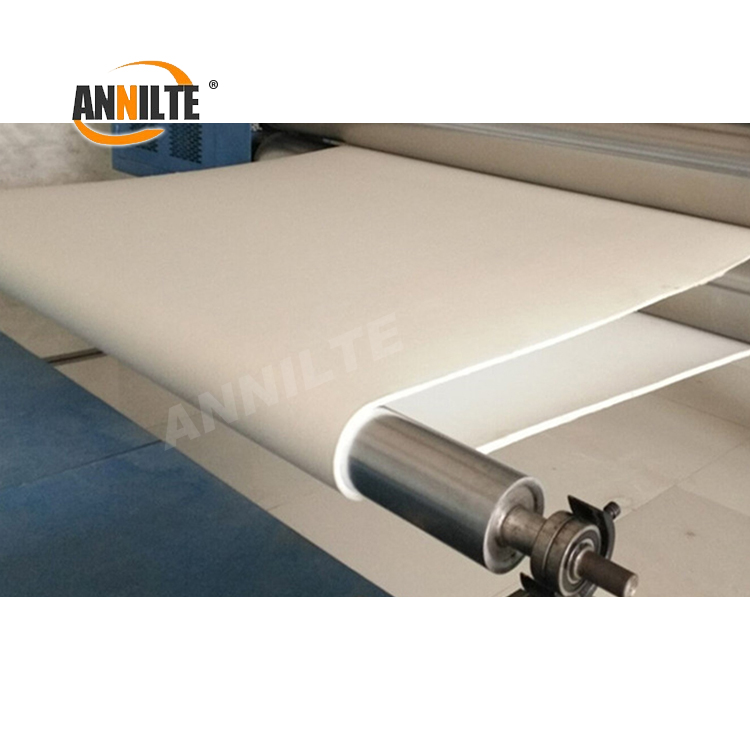

The purpose of a transfer printing machine is to transfer and fix colours from a transfer paper to textile with a heated drum. This sublimation process requires however a regular temperature of the heated drum. Once the requested temperature is reached, sublimation takes place as the transfer paper and the fabric are brought together during their run around the heated roll by the Nomex® endless felt, also called Nomex® blanket or sublimation felt. It can be used for the printing of curtains, bedcovers and non woven fabrics made of polyester, nylon, acrylic and blends. This type of machine has several advantages : it does not need much place, there is no need of finishing for the printed fabrics, the time of process is quite short, the machine is easy to maintain, it does not need water, it does not need solvents.

Technical data

1.Endless needled felt made from high temperature-resistant meta-aramid fibres

2.Operating temperature: 230°C, short term up to 250°C

3.Each felt is individually produced, depending on the intended application

4.Our felts has circular industrial fabric, Can achieve ultra-low shrinkage

Specification

|

Endless Felt for Transfer Printing Machine |

|

| Material | 100% nomex |

| Density | 2200g/m2~4400g/m2 |

| Thickness | 6mm~12mm |

| Width | 600mm~3800mm,OEM |

| Inner circumference | 1200mm~30000mm,OEM |

| Thermal shrinkage | ≤1% |

| Work temperature | 200℃~260℃ |

| Working life | 4000 hours |

| Packing | Plastic film,Cushion,Woven bag. |

| Lead time | Within 15 days after deposit |

| Payment | T/T,Western Union,L/C |

Product Advantages

High temperature resistance:

using high quality raw materials, the high temperature resistance range can reach 100~260℃, also can be seamlessly connected

Good abrasion resistance:

After special process, it keeps a better physical state and reduces abrasion and damage.

Low shrinkage:

the use of anti-shrinkage treatment technology, with a thermal shrinkage rate of less than 0.8%.

High flatness:

By adjusting the arrangement and density of fibers to get a flatter surface.

Applicable Scenarios

Applicable thermal transfer processes

> High temperature sublimation transfer (such as ceramic cups, metal plates, chemical fiber fabrics)

> Industrial hot stamping/foil stamping (requires long time high temperature pressurization)

> PCB circuit board lamination transfer

> High-precision digital inkjet thermal transfer

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/