Heat Resistant Nomex Felt Conveyor belt

Nomex felt conveyor belts are high performance industrial conveyor belts that are widely used in high temperature, corrosive environments or where high strength and durability are required.

The Specifications of Felt Conveyor Belt

| Material | 100% nomex |

| Density | 2200g/m2~4400g/m2 |

| Thickness | 2mm~12mm |

| Width | 150mm~220mm,OEM |

| Inner circumference | 1200mm~8000mm,OEM |

| Thermal shrinkage | ≤1% |

| Work temperature | 200℃~260℃C |

Product Advantages

High temperature resistance:

using high quality raw materials, the high temperature resistance range can reach 100~260℃, also can be seamlessly connected

Good abrasion resistance:

After special process, it keeps a better physical state and reduces abrasion and damage.

Low shrinkage:

the use of anti-shrinkage treatment technology, with a thermal shrinkage rate of less than 0.8%.

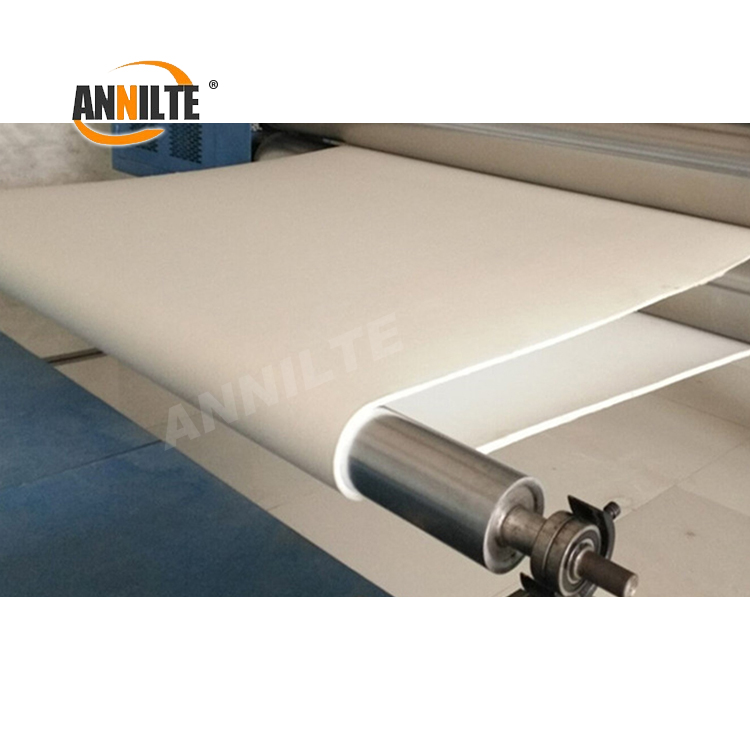

High flatness:

By adjusting the arrangement and density of fibers to get a flatter surface.

Common Felt Belt Joints

Seamless joints:

For special applications, such as conveyor lines that require extreme precision and stability, seamless joints can be used. This method seamlessly connects the two ends of the belt through a special process, thus eliminating stress concentration and friction loss at the joint.

Steel Buckle Joints:

A steel buckle joint is a way of joining two ends of a conveyor belt together using steel buckles. This method is used in scenarios where quick attachment and removal is required, such as temporary conveyor lines or lines that require frequent belt changes.

Applicable Scenarios

High temperature felt conveyor belt is widely used in many fields because of its unique performance:

Textile industry: Commonly used in textile machinery, such as looms and knitting machines, for conveying fibers, thread balls and fabrics.

Printing industry: In printing machinery, it is used to transfer paper and ensure that the paper passes smoothly through the printing area to improve print quality.

Food processing: It can be used in food production such as baking, cooling and packaging, and is particularly suitable for conveying food products that tend to stick or require soft contact.

Wood processing: In wood processing machinery, it is used for conveying boards, battens, etc. Its non-slip characteristics help keep the material stable.

Glass manufacturing: in glass production lines, for conveying glass sheets, its flat surface reduces the risk of scratching the glass.

Electronics industry: In the assembly and testing of electronic components, it can be used to convey sensitive parts, and its anti-static properties help protect electronic components.

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/