Perforated egg collection belt,perforated egg conveyor belt

Through innovative structural design and material application, the perforated egg picking belt effectively solves the problems of low efficiency, high breakage rate, and difficult to guarantee hygiene of the traditional egg picking method, and becomes an indispensable automation equipment for modern poultry farms. Choose the right product and standardized use, can significantly improve the breeding efficiency, promote industrial upgrading.

Structural composition

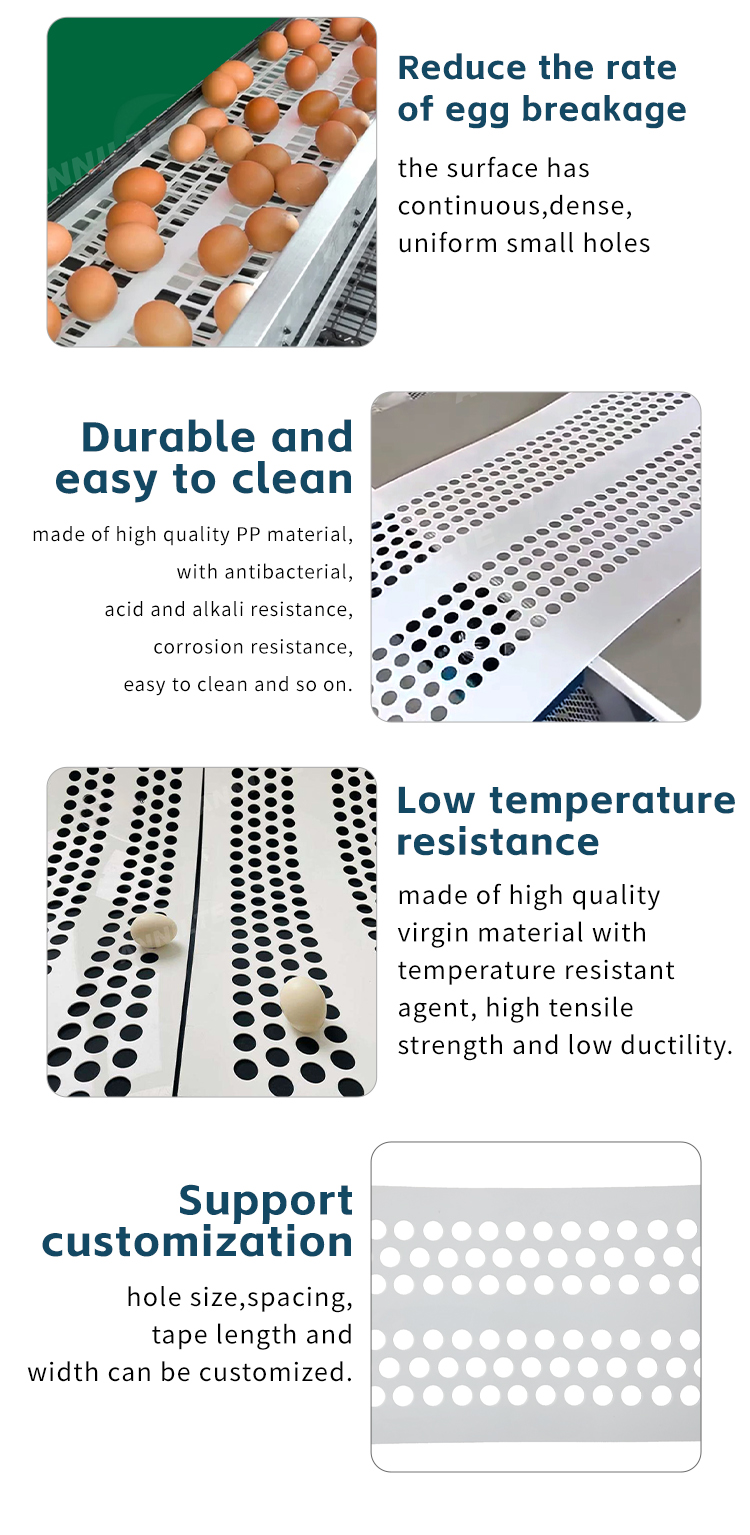

Main material: Usually made of high-strength polypropylene (PP) or PVC, which is wear-resistant, corrosion-resistant and anti-aging.

Hole design: The surface of the conveyor belt is evenly distributed with round or square holes, the diameter of which is customized according to the size of the eggs (e.g. diameter of about 40-45mm) to ensure that the eggs are stable and do not slip after being stuck into the conveyor belt.

Spcification Of Perforated Eggg Belt

Common sizes: 100mm, 200mm, 350mm, 500mm, 700mm (can be customized to 0.1-2.5 meters)

Standard thickness: 0.8-1.5mm, tensile strength up to 100N/mm² or more

Single roll length: 100m (standard), 200m (customized), support continuous splicing use

Our Product Advantages

Applicable Scenarios

Scale egg farms

Suitable for cascade and ladder type chicken cage system, seamlessly connecting with automated egg collection equipment.A single egg collection belt can cover multiple rows of cages, realizing centralized egg collection.

Research and Breeding Bases

For egg collection from experimental flocks to ensure data accuracy and biosecurity.

Food processing enterprises

Equipped with egg grading, cleaning and packaging production lines to enhance the efficiency of raw material processing.

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/