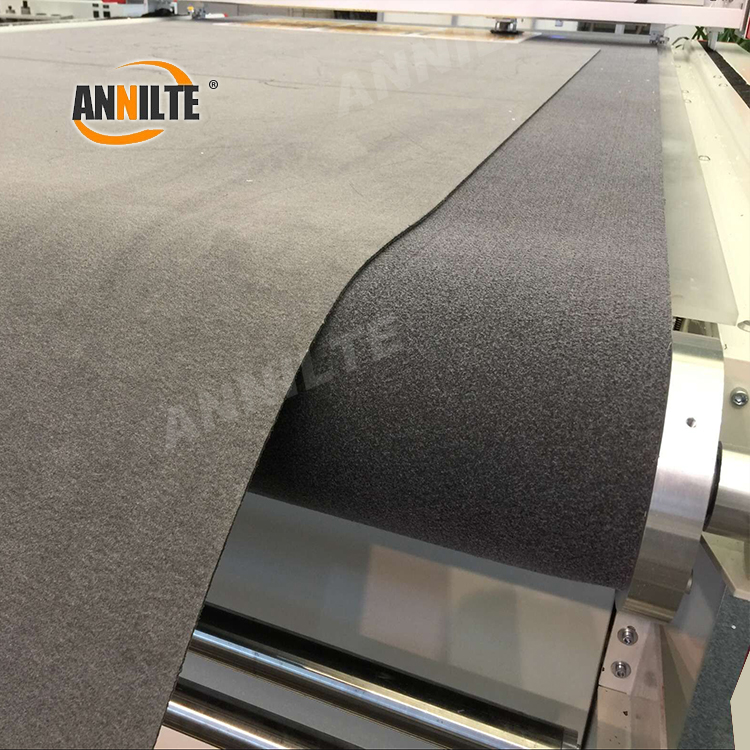

Single Side Felt Conveyor Belt

In the wave of industrial automation and efficient production, the performance of conveyor belt, as the “blood vessel” connecting the production link, directly determines the production efficiency and product quality. As a professional felt belt manufacturer, we have ploughed into the field of conveyor belts for many years, with single-sided felt conveyor belts as the core products, providing non-slip, wear-resistant, noise reduction and high-quality solutions for the electronics, textile, food, packaging and other industries, helping enterprises to reduce costs and increase efficiency, and realize intelligent upgrading.

The Specifications of Felt Conveyor Belt

| Part number | Name | Color(superface/subface) | Thickness (mm) | Texture(surface/tensile layer) | Weight (kg/㎡) |

| A_G001 | Double-faced felt belt | Dark black | 1.6 | Felt/Felt | 0.9 |

| A_G002 | Double-faced felt belt | Dark black | 2.2 | Felt/Polyester | 1.2 |

| A_G003 | Double-faced felt belt | Dark black | 2.2 | Felt/Felt | 1.1 |

| A_G004 | Double-side felt belt | Dark black | 2.5 | Felt/Felt | 2.0 |

| A_G005 | Double-side felt belt | Dark black | 4.0 | Felt/Polyester | 2.1 |

| A_G006 | Double-faced felt belt | Dark black | 4.0 | Felt/Felt | 1.9 |

| A_G007 | Double-side felt belt | Dark black | 5.5 | Felt/Felt | 4.0 |

| A_G008 | single side felt belt | Dark black | 1.2 | Felt/Fabric | 0.9 |

| A_G009 | single side felt belt | Dark black | 2.5 | Felt/Fabric | 2.1 |

| A_G010 | single side felt belt | Dark black | 3.2 | Felt/Fabric | 2.7 |

| A_G011 | single side felt belt | Dark black | 4.0 | Felt/Fabric | 3.5 |

| A_G012 | single side felt belt | Grey | 5.0 | Felt/Fabric | 4.0 |

Product Category

Felt conveyor belts are mainly divided into two types: single-side felt conveyor belts and double-side felt conveyor belts:

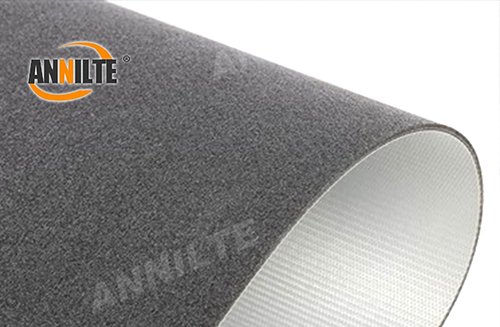

Single side felt conveyor belt: one side is felt layer, the other side is pvc belt. Its structure is relatively simple, low cost, suitable for some of the felt thickness requirements of the scene is not high.

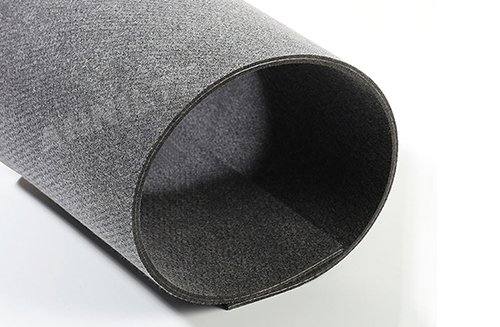

Double Sided Felt Conveyor Belt: Both sides are covered with felt layer, providing better friction and cushioning effect. Its structure is a bit more complicated, but it can better meet some special needs, such as occasions requiring bidirectional transmission.

1、Relatively simple structure and low cost.

2、Friction is concentrated on the side with felt, making it suitable for use in situations where specific friction is required.

3、The cushioning effect is relatively weak, but sufficient for some basic transmission needs.

1、The structure is relatively complex, but provides better friction and cushioning.

2、Felt layers on both sides make the friction more uniform and can better protect the items on the conveyor belt.

3、The cost is relatively high, but it can meet some special needs.

Our Product Advantages

1. Anti-slip and wear-resistant, precise transportation

Single-sided felt design through the high-density fiber structure, the coefficient of friction increased by 30%, effectively preventing the material from slipping and shifting, especially suitable for the transmission of precision components and fragile items. Whether it is circuit boards, glass products or food packaging, it can ensure zero damage and zero waste.

2. Shock absorption and material protection

The felt layer is soft and elastic, which can absorb the impact and reduce the collision damage of materials in the transmission process. For fragile electronic components or fragile products, the single-sided felt conveyor belt can be called “invisible shield”, reducing the defective rate up to 20%.

3. Quiet and environmentally friendly, comfortable production

The natural sound-absorbing property of felt can reduce the noise of equipment operation by 5-8dB, improve the workshop environment and meet the green production concept of modern factories.

4. Flexible customization, suitable for multiple scenarios

From thickness (1-10mm) to width (can be customized to more than 2 meters), from temperature resistance (-20 ℃ to 150 ℃) to anti-static, flame retardant and other special features, we provide full-dimensional customization services to meet the individual needs of different industries.

Product Process

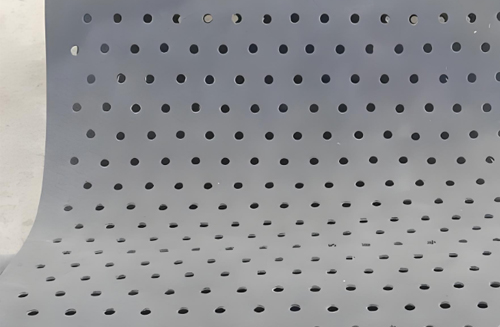

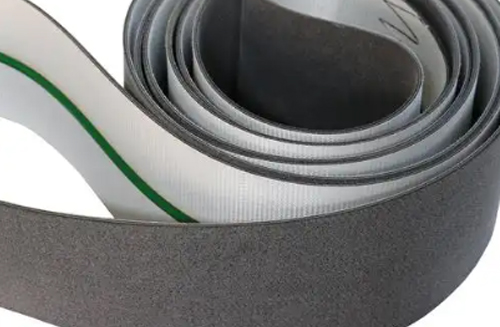

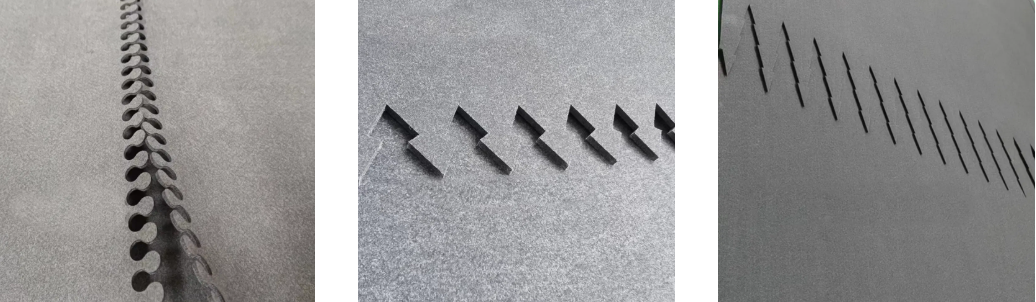

The processing of felts includes the steps of adding guides and punching holes. The purpose of adding guides is to enhance the durability and stability of the felt and to ensure that it will not be deformed or deflected in the course of use. The holes are punched for precise positioning, air absorption and ventilation.

Felt Belt Perforation

Add Guide Bar

Common Felt Belt Joints

Toothed Joints

Skew Lap Joint

Steel Clip Connectors

Applicable Scenarios

Electronic industry: used for circuit boards, semiconductors and other precision components conveyance, to prevent scratches and static electricity damage.

Textile industry: conveying soft materials such as fabric and leather to avoid surface abrasion.

Food processing: as a conveyor belt surface to prevent food from slipping, while being easy to clean.

Packaging industry: for conveying materials such as cartons, bottles and cans to provide stable friction

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

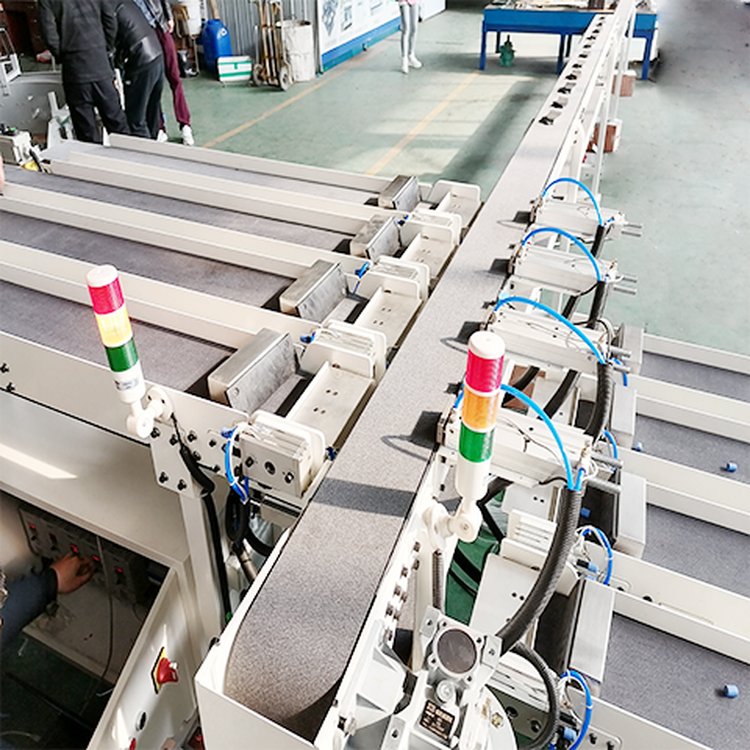

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/