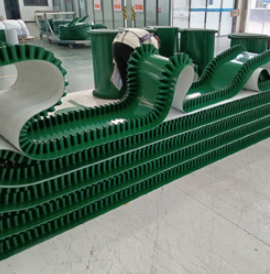

Sidewall Conveyor Belt /Skirt Edge Baffle Conveyor Belt

Product introduction of skirt edge baffle conveyor belt

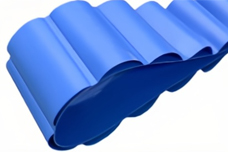

Skirt baffle conveyor belt is a kind of special conveyor belt combining skirt (side baffle) and baffle (transverse partition), which is designed to effectively prevent materials from scattering and is suitable for inclined or vertical conveying scenes.

It can make all kinds of bulk materials to be continuously conveyed at any inclination angle from 0 to 90 degrees, and has the features of large conveying angle, wide range of use, small footprint. No transfer point, reduce the investment in civil engineering, low maintenance cost, large conveying capacity, etc., to solve the ordinary conveyor belt or patterned conveyor belt can not reach the conveying angle. Corrugated edge conveyor belt can be designed into a complete set of conveying system according to the requirements, avoiding intermittent conveying and complex conveying lifting system.

Large conveying angle

1、Good wear-resistant and anti-slip performance

2、Prevents overflowing and slipping of conveyed goods

3、Can complete the 0-90 ° slope climbing conveying

Conveying bulk materials

1、Suitable for conveying easily dispersed

2、Powdery, granular, small pieces of materials

3、such as biomass pellets, feed, etc.

No hidden material leakage

1、Seamless skirt process

2、Avoid material accumulation

3、No material hiding, no material leakage, no material spreading.

Support customization

1、Specification according to the different needs of customers

2、Can be customized

3、Meet customer requirements

Product Selling Points

Applicable Scenarios

Scene characteristics: conveying powdery, granular or easily scattered materials.

Agriculture: conveying grain, feed, fertilizer, etc. Chemical plant: transporting powdery chemical raw materials (such as plastic granules, calcium carbonate). Food processing: conveying sugar, salt, flour and other materials that are easy to fly.

Industrial production

Biomass Pellet Conveying

Logistics

Fertilizer Bulk Conveying

Electronics Industry

Feed Conveying

Food Industry

Wine Lees Conveying

Customized Scope

Annilte offers a wide range of customization options, including band width, band thickness, surface pattern, color, different processes (add skirt, add baffle, add guide strip, add red rubber), etc., which can meet the needs of different customers.

For example, the food industry may need oil and stain resistant properties, while the electronics industry needs anti-static properties. No matter which industry you are in, ENERGY can customize for you to meet the needs of various special working conditions.

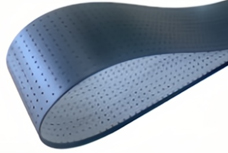

Add skirt baffles

Guide bar processing

White Conveyor Belt

Edge Banding

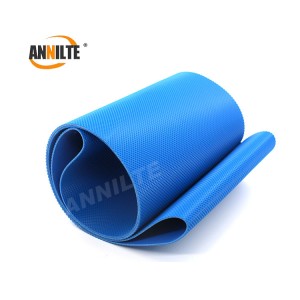

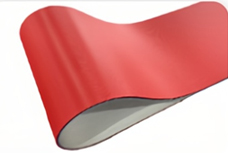

Blue Conveyor Belt

Sponging

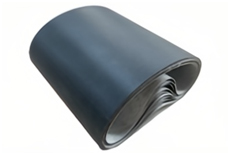

Seamless Ring

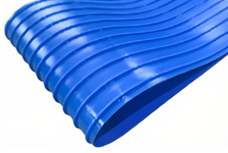

Wave processing

Turning machine belt

Profiled baffles

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/