Annilte Flat belts for box gluers / laminators in the printing industry

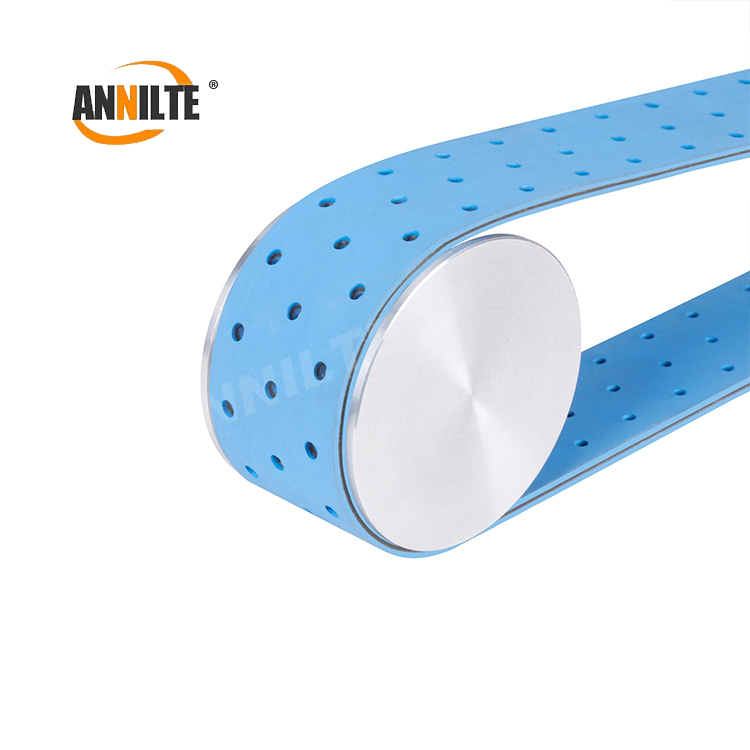

The laminator belt can be made of double-ran sheet base material and rubber material, the surface color can be made of green \ red and grey, and the diameter of the perforation can be 6mm, 8mm and 10mm.

Perforation types are: double rows of holes, four rows of holes, 5-2 holes, 5-4 holes, etc., commonly used in laminating machines and corrugating machines for paper transmission!

Perforation need to provide drawings, can be customized to drawings and samples, batch customization price is lower!

Our Product Advantages

Strong abrasion resistance: with super abrasion-resistant rubber layer or high-strength sheet base layer, such as super abrasion-resistant rubber layer design, can make the box surface without indentation and long belt life.

High tensile strength: with high-strength aramid nylon core as the strong layer, the tensile strength is enhanced, the size is stable, not easy to stretch, and prolong the service life.

Adapt to harsh working conditions: some belts are made of special materials and processes, such as high temperature resistant and chemical resistant rubber, to adapt to the needs of different production environments.

Product Categories

Perforated and glued flat belts combine two special processes, perforation and gluing, and have a wide range of applications in industrial automation and material transfer, especially in scenarios where adsorption, positioning, high temperature resistance or enhanced friction are required.

Applicable Scenarios

Printing and packaging machinery (e.g. paper laminating machine, tile laminating machine, corrugating machine, laminating machine, etc.):

The suction channel is formed by punching holes, and negative pressure is generated with the vacuum pump, so that paper, cardboard and other light materials are close to the surface of the belt, preventing them from floating or being misplaced during the conveying process.

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/